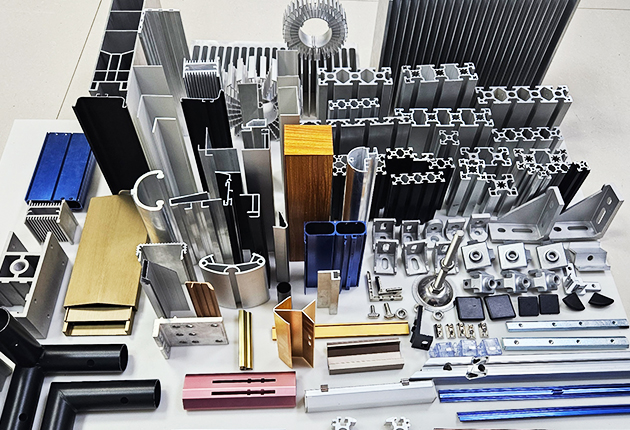

Aluminum Profile Production and Quality Control Process

2023-03-13

At our aluminum extrusion factory, we strictly manage each stage of the production process to ensure that every aluminum profile meets international standards and customer requirements. Below is an overview of our production steps and quality control measures.

1. Raw Material Inspection

We use high-quality aluminum ingots (6063, 6061, etc.) as raw materials. Before production, every batch undergoes chemical composition testing to ensure consistency and compliance with alloy standards.

2. Melting and Casting

Aluminum ingots are melted in a furnace and cast into billets. Our automatic casting lines ensure uniform billet structure and stable composition. During this stage, we test for impurities, gas content, and density to avoid casting defects.

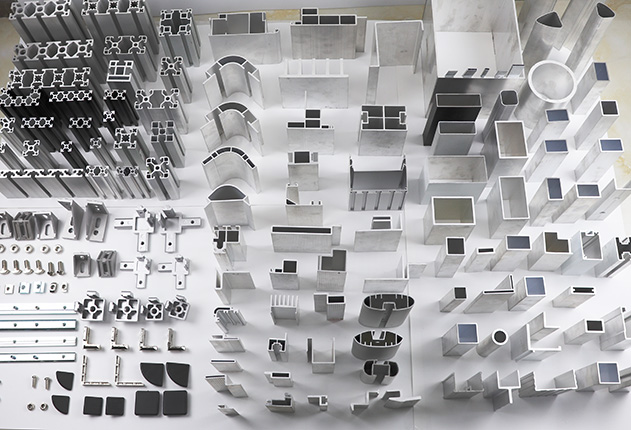

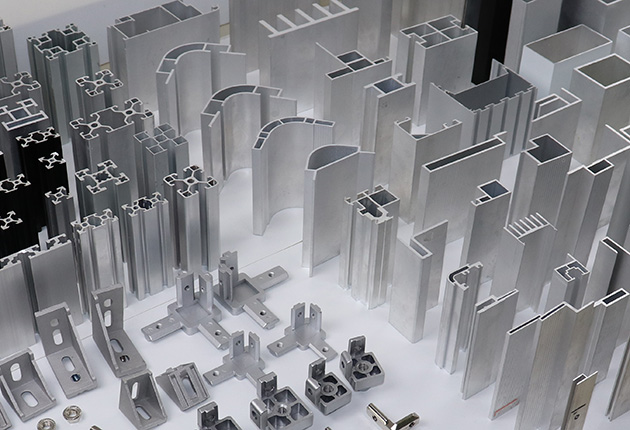

3. Extrusion Process

The cast billets are preheated and extruded using advanced 15000-ton extrusion presses. Our skilled operators and digital control systems ensure precise shape, dimensions, and wall thickness.

4. Cooling and Stretching

After extrusion, profiles are rapidly cooled to maintain structural integrity. Then, stretching equipment corrects any deformation and improves mechanical properties. Each profile is straightened and stress-relieved.

5. Cutting and Aging

Profiles are cut to standard or custom lengths. To enhance hardness and strength, we apply aging treatment (artificial heat aging) under controlled temperature and time.

6. Surface Treatment

1.We provide various surface finishing options including:

2.Anodizing: for corrosion resistance and color finish.

3.Powder Coating: for decorative color options and protection.

4.Wood Grain Transfer: for aesthetic appearance in architectural use.

Each surface treatment line follows strict parameters for thickness, adhesion, and uniformity.

7. Quality Inspection

Throughout the process, we conduct multiple quality checks:

1.Dimension inspection with calipers and micrometers.

2.Hardness and tensile strength tests to ensure mechanical performance.

3.Surface appearance inspection for scratches, dents, or coating defects.

4.Corrosion resistance testing after anodizing or coating.

We follow ISO 9001 quality management system and can provide factory test reports (EN/ASTM standards) upon request.

8. Packaging and Shipping

Final products are carefully wrapped with protective film, kraft paper, and shrink film, then packed in wooden crates or steel racks. Customized packaging is available for overseas clients to prevent damage during transport.