Professional Powder Coating Process for Aluminum Profiles

2023-04-12

Powder coating is one of the most important surface treatment processes in the aluminum profile industry. It not only enhances the aesthetic appearance of aluminum profiles but also significantly improves their corrosion resistance and durability. Our factory is equipped with an advanced fully automatic powder coating line, ensuring efficient, uniform, and high-quality surface finishes.

What is Powder Coating?

Powder coating is a dry finishing process that uses electrostatic spraying to apply thermoset or thermoplastic powder to the surface of aluminum profiles. After application, the coated aluminum is heated in a curing oven, where the powder melts and forms a smooth, hard finish.

Compared to traditional liquid coatings, powder coating is more environmentally friendly, with no volatile organic compounds (VOCs) and minimal waste.

Steps in the Powder Coating Process

1.Pre-Treatment: Aluminum profiles undergo degreasing, cleaning, and chemical conversion to remove surface contaminants and improve coating adhesion.

2.Drying: After cleaning, profiles are thoroughly dried to ensure no moisture interferes with the coating.

3.Electrostatic Spraying: Powder is evenly sprayed onto the surface of the aluminum profile using electrostatic equipment.

4.Curing: Profiles are moved into a curing oven, where the powder melts and forms a durable, uniform coating layer.

5.Cooling and Inspection: The coated profiles are cooled and inspected for thickness, color uniformity, and adhesion strength.

Advantages of Powder Coating

1.Corrosion Resistance: Provides a strong protective barrier, especially in humid or industrial environments.

2.Enhanced Aesthetics: Offers a wide range of color options and smooth finishes.

3.Durability: High resistance to scratches, chipping, and fading.

4.Environmentally Friendly: Free of solvents and hazardous emissions.

5.Cost-Effective: High material utilization rate with less waste.

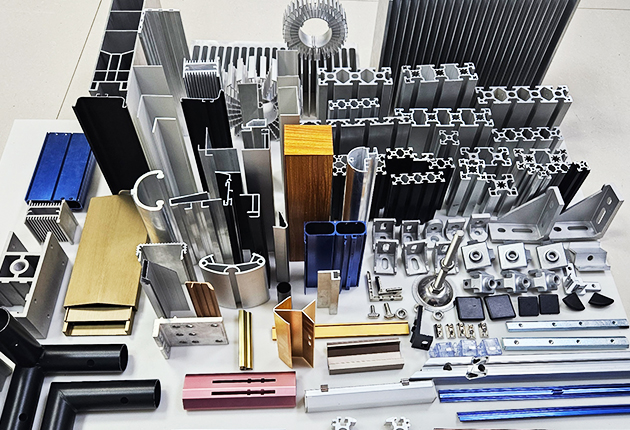

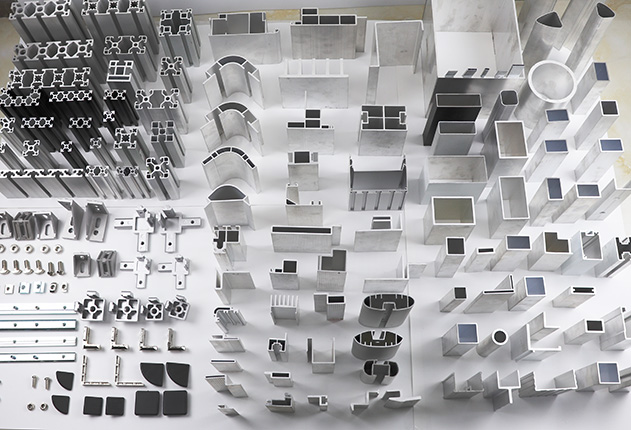

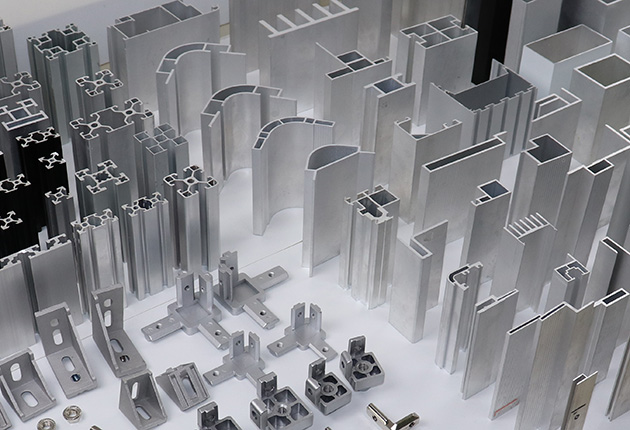

Applications of Powder-Coated Aluminum Profiles

Powder-coated aluminum profiles are widely used in:

Building and construction (doors, windows, curtain walls)

Automotive components

Furniture frames

Solar panel brackets

Electrical enclosures

Our powder coating line supports custom colors and gloss levels to meet the specific needs of different industries.

Conclusion

A high-quality powder coating process is essential for extending the service life and enhancing the visual appeal of aluminum profiles. With our advanced equipment and strict quality control, we provide powder-coated products that meet both functional and aesthetic standards.