Aluminum Profile Anodizing: A Key Surface Treatment Technology

2023-05-05

Anodizing is one of the most important surface treatment processes for aluminum profiles. This electrochemical process significantly improves the corrosion resistance, surface hardness, and aesthetic appearance of aluminum, making it widely used in construction, industrial, and decorative applications.

What Is Anodizing?

Anodizing is an electrochemical oxidation process. During the process, the aluminum profile acts as the anode and is immersed in an electrolyte. Under the action of an external current, a dense oxide film forms on the surface of the aluminum. This oxide layer is hard, porous, and has good adhesion, providing the aluminum profile with excellent durability and surface texture.

Benefits of Anodized Aluminum Profiles

1.Improved Corrosion Resistance: The oxide film effectively isolates the aluminum base from the air and moisture, preventing corrosion.

2.Increased Surface Hardness: Anodizing significantly increases the surface hardness, improving wear resistance.

3.Enhanced Aesthetic Appeal: After anodizing, aluminum profiles can be dyed in various colors, offering both protection and decoration.

4.Better Adhesion for Coatings: The porous structure of the oxide layer enhances the adhesion of paints, adhesives, and coatings.

5.Environmentally Friendly and Non-Toxic: The anodizing process does not involve heavy metals or harmful chemicals and complies with environmental standards.

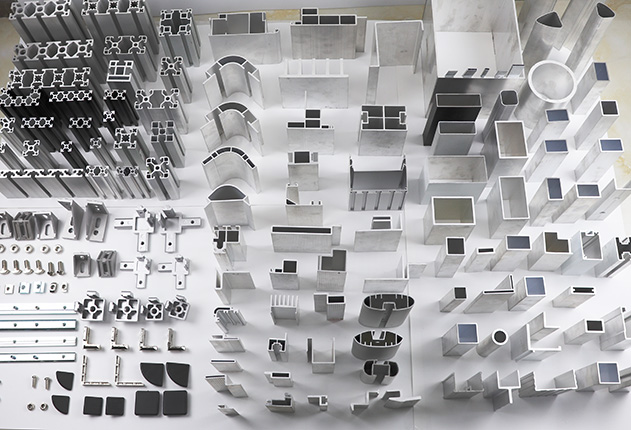

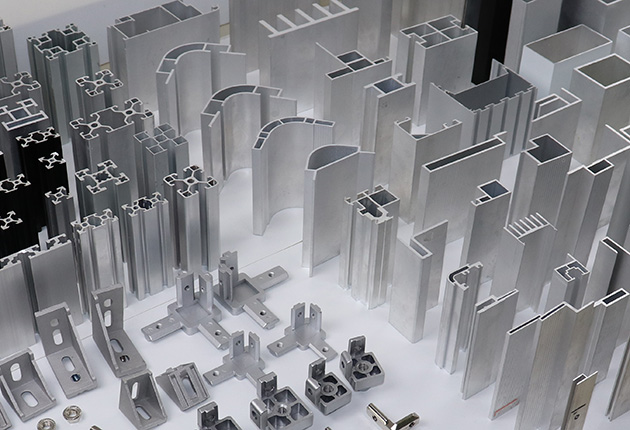

Common Anodizing Types

1.Natural Color Anodizing (silver white)

2.Electrolytic Coloring (bronze, black, champagne, etc.)

3.Hard Anodizing (used for aerospace, machinery parts, etc.)

4.Acid Anodizing (used for ultra-thin oxide layers)

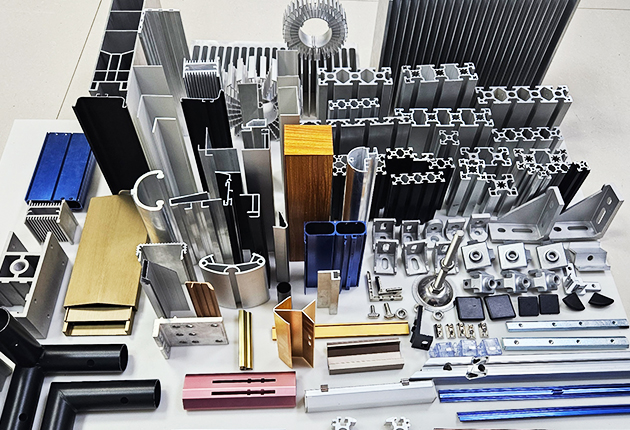

Application Areas

1.Construction and Architecture: Window and door frames, curtain walls, decorative panels

2.Electronics: Enclosures, heat sinks, mobile phone frames

3.Machinery and Equipment: Precision components, tracks, brackets

4.Home Products: Furniture, kitchenware, lamps

Our Advantages

As a professional aluminum profile manufacturer, we not only have advanced anodizing production lines, but also offer customized color and finish services. We strictly control every step of the process to ensure uniform color, fine texture, and excellent adhesion of the oxide layer. Whether you need architectural-grade or industrial-grade surface treatments, we can deliver solutions tailored to your needs.