Aluminum Profile Cutting: The Key Step for High-Precision Custom Services

2024-03-21

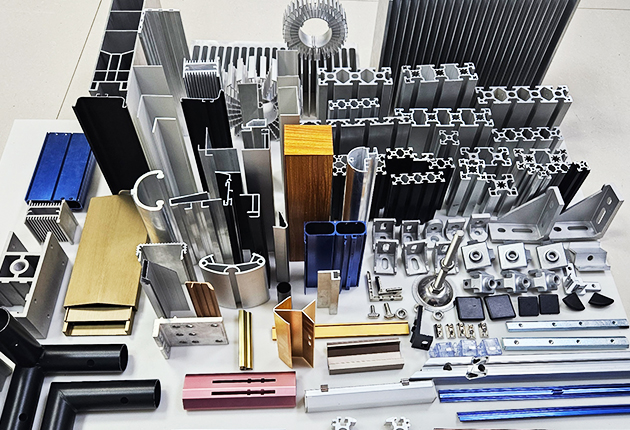

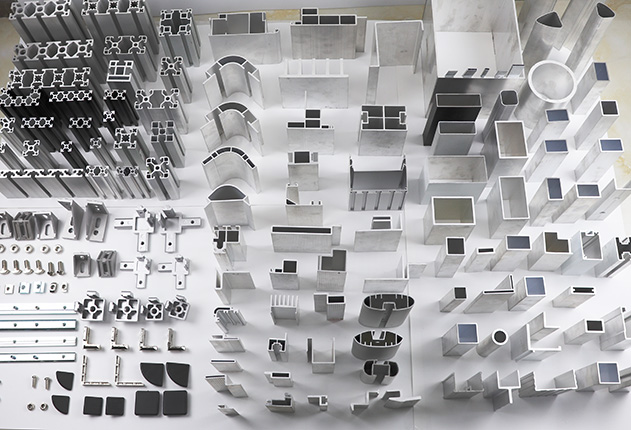

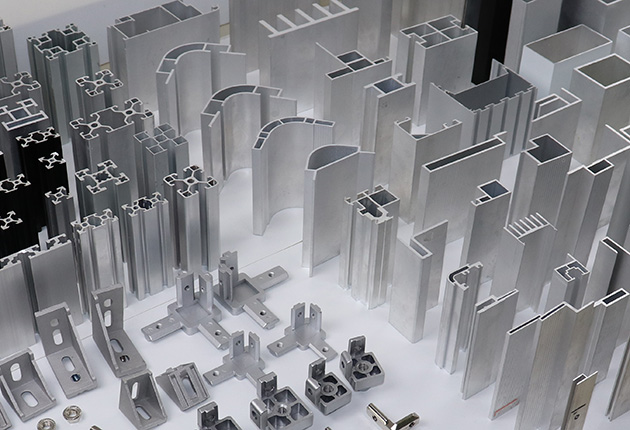

Cutting is a critical step in the processing of aluminum extrusion profiles. Whether for architectural structures, industrial equipment, or automotive components, the precision and efficiency of cutting directly impact assembly quality and product performance.

1. Common Cutting Equipment for Aluminum Profiles

1.CNC Precision Sawing Machines: Programmable control, suitable for high-precision and large-scale cutting.

2.Single/Double Head Cutting Machines: Suitable for window frame and door frame profiles.

3.Laser Cutting: Used for industrial parts with complex cross-sections and high requirements.

4.Auto Feeding Lines: Achieve efficient operation in conjunction with cutting equipment.

We use CNC precision saws and automatic feeding lines to ensure consistent, accurate cutting for aluminum profiles. Special shapes or tight tolerances are handled with customized blades or laser cutters.

2. Tolerance Control and Precision Level

The standard cutting tolerance is within ±0.2mm, and for some high-demand applications, we can achieve ±0.05mm. We also provide deburring and angle adjustment to guarantee clean and accurate cuts.

3. Application Scenarios: From Industrial Frames to Precision Assemblies

1.Building curtain wall system

2.Electronic and electrical bracket

3.Solar bracket system

4.Battery boxes, automotive structural components

Cutting accuracy ensures proper fit and structural strength in solar systems, EV battery frames, architectural curtain walls, and electronic enclosures.

4. We Provide Custom Aluminum Cutting Services

We offer tailor-made cutting services based on your drawings or samples. Our one-stop aluminum processing includes cutting, drilling, and punching, helping clients improve efficiency and reduce cost.