.png)

Design sketch ▲

According to the detailed calculation of the feasibility report, the cost of the all-aluminum bridge is equal to the cost of the steel bridge. Although the price of aluminum is higher than that of steel, aluminum bridges are compensated for by the lower cost of other structures than steel bridges, such as towers, hangers, and main cables. In addition, in the calculation of the cost, the aluminum bridge "lifetime" without maintenance, maintenance savings, and the high value of recycling scrap aluminum after expiration are not included.

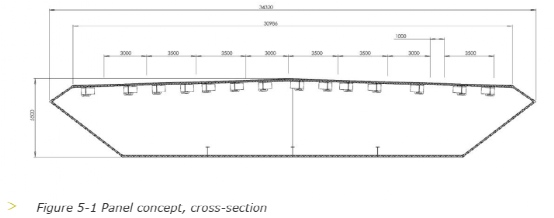

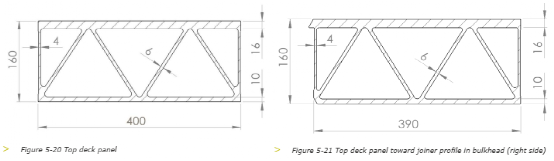

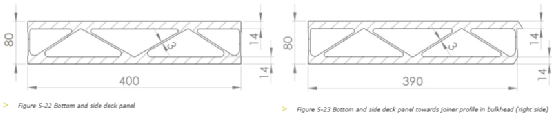

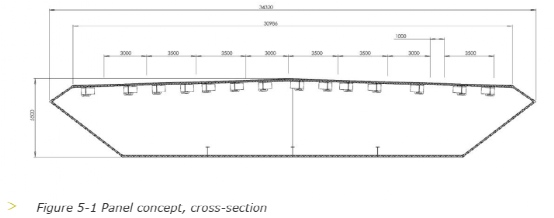

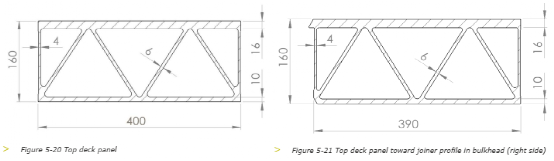

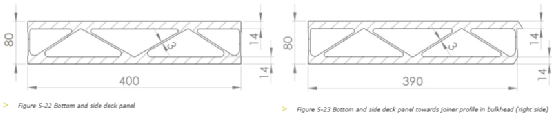

A feasible scheme proposed in the research report (Panel concept) is to use aluminum alloy profiles plus friction stir welding. The bridge section structure is shown in the figure below.

The upper and lower layers of the bridge deck are made of EN AW6005A-T6 aluminum alloy extrusions and joined by friction stir welding (FSW). The aluminium is supplied by Hydro and is a low-carbon aluminium with carbon emissions of less than 4 tonnes CO2 per tonne of aluminium.

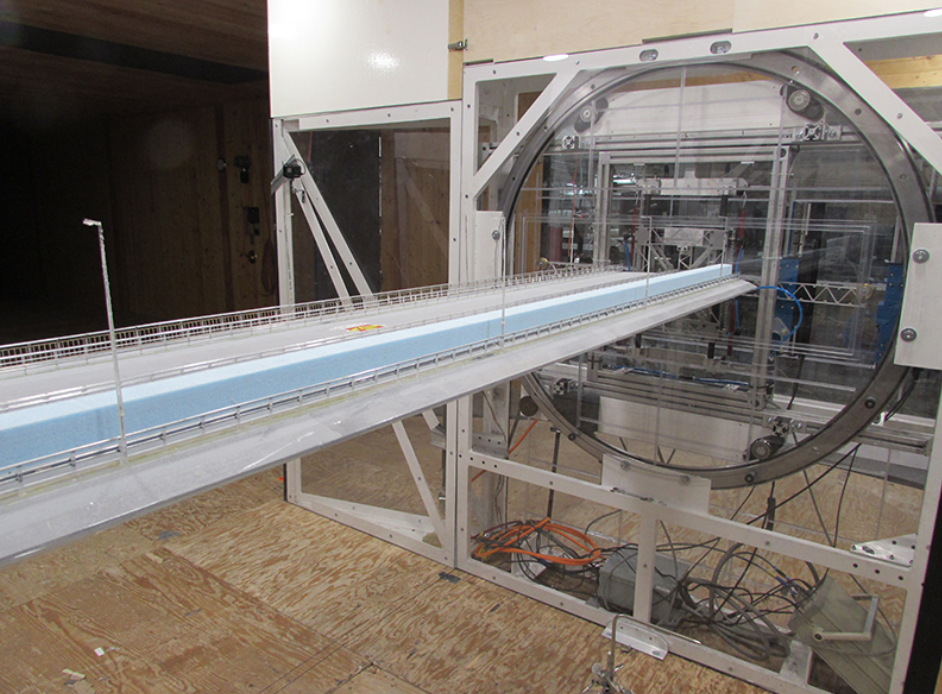

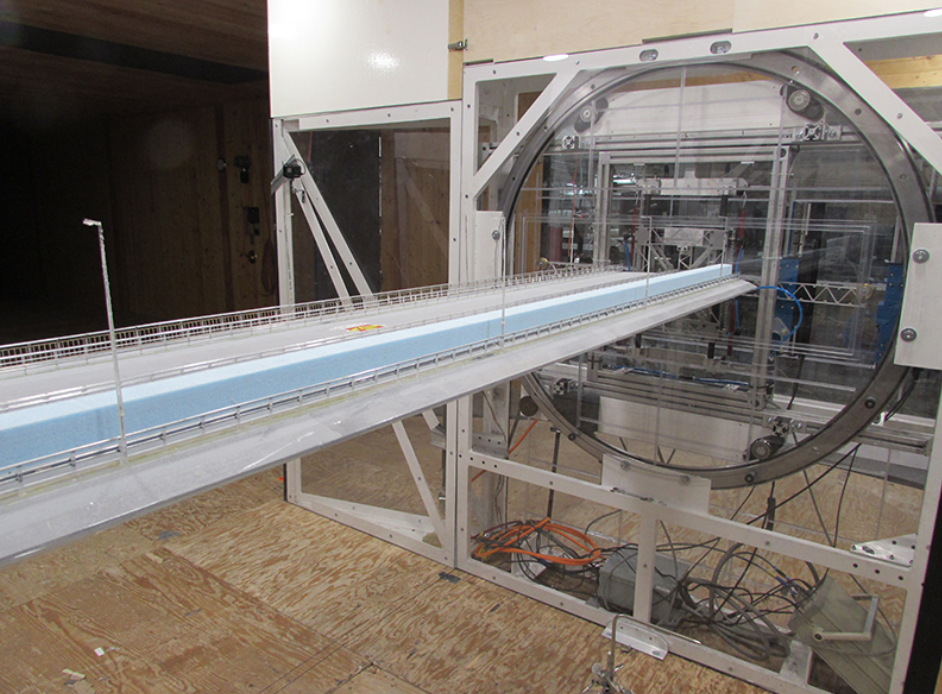

Since no such aluminum bridge has been built in the world before, and no such large highway aluminum bridge has been built, many challenges are faced at the technical level, such as overall stability, local stability, fatigue performance, overall limit stress, deflection, etc., which must be solved one by one, but these problems have been carefully studied before construction.

Daniel Tran, risk engineer at Norway Public Roads Administration, said: "Aluminum has many advantages, such as corrosion resistance oxide film on aluminum surface, aluminum bridge does not need to be painted, and it does not corrode. Aluminum parts in the bridge can be recycled 100%, so aluminum is both an environmentally friendly material and a low-cost material."

Located in Langenuen, about 45km south of Bergen, it is a bridge on the newly built Norway coastal highway E39 and one of the largest projects in Norway. After the bridge is opened to traffic, it can shorten the distance and reduce the transportation cost. At the same time, the construction of this suspension bridge with aluminum instead of steel not only shortens the construction time, saves the construction cost and construction materials, but also reduces the maintenance workload in the later period. At the same time, the accumulated experience is beneficial to the construction of other suspension bridges.

It is understood that the bridge aluminum is provided by Hydro Aluminum Company, and most of the structural aluminum is extruded with 6061 alloy. Alloy 6061 can be processed into a variety of semi-finished products, such as plates, strips, tubes, rods, shapes, and wires. The temperature of solution treatment is 515℃~525℃, but it cannot be greater than 550℃. The density at 20℃ is 2.7g/cm3, the solidus temperature is 582℃, the liquidus temperature is 652℃, the linear expansion coefficient at 20℃~100℃ is 23.6×10-6/℃, and the specific heat at 20℃ is 896J/(kg·℃). In addition, 6061 alloy has excellent low temperature properties, no low temperature brittleness, tensile strength at-269℃ is 56.5% higher than that at 25℃, elongation is 8 percentage points higher, and it is a good material for manufacturing equipment structure.

use of steel structures for bridges, especially after the Hong Kong-Zhuhai-Macao Bridge was put into operation in 2019, which has further consolidated China's indisputable leading position in this field. Although China has built nearly 80 aluminum bridges so far, they have been well received in use. At the same time, it has gone abroad and built a pedestrian bridge in Doha. However, these bridges are all street bridges in cities and have not yet seen road bridges. Especially the relevant media reports on the construction of large-span aluminum bridges for heavy-duty expressways, there is still a certain gap compared with Nordic and North American countries in this field, which needs to be filled up urgently, especially in promoting aluminum applications. Moreover, at present, China has about 160 large extruders with extrusion force ≥45MN, including 2 sets of unparalleled 225MN super extruders, which can produce a variety of complex cross-section profiles required for national economic construction, so the construction of large extruded aluminum profiles for bridges is of course not a problem.

.png)