Application of 15,000-Ton Extrusion Presses in Aluminum Profile Extrusion

2023-04-06

In the modern aluminum profile manufacturing industry, the 15,000-ton extrusion press plays a pivotal role. With its ultra-high tonnage and powerful extrusion capabilities, it is particularly suitable for producing large cross-sectional profiles and high-strength industrial aluminum profiles.

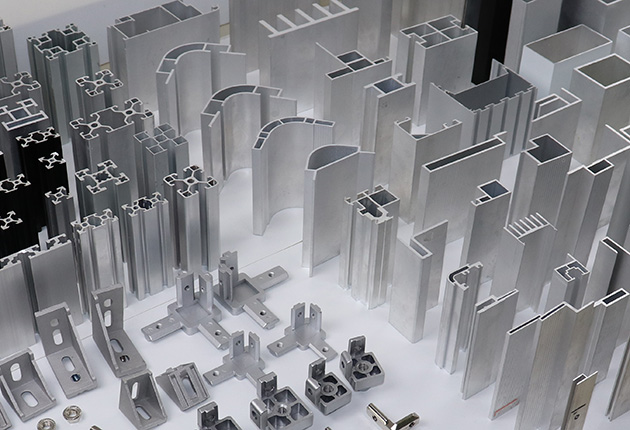

1. Equipment Overview

The 15,000-ton aluminum extrusion press belongs to the category of ultra-large extrusion equipment. Its main functions include:

Generating ultra-high pressure to extrude aluminum alloy billets through a mold, forming specific cross-sectional profiles.

Capable of extruding large-size industrial aluminum profiles, such as thick-walled tubes, rods, and structural components used in the aerospace, transportation, and construction sectors.

Equipped with precision-controlled hydraulic systems and automated feeding and discharging mechanisms, ensuring high efficiency and quality stability.

2. Technical Advantages

Compared to conventional extrusion machines, the 15,000-ton extrusion press offers the following technical advantages:

Strong Extrusion Capability: Can extrude large cross-sectional and high-strength alloys such as 6061 and 6063.

Stable Temperature Control: Supports strict temperature management for extrusion cylinders and billets, ensuring optimal alloy mechanical properties.

Precision Mold Matching: Compatible with large molds, effectively reducing deformation and improving product surface quality.

Automation and Intelligence: Modern equipment often integrates PLC control systems and real-time monitoring devices, greatly improving production efficiency and safety.

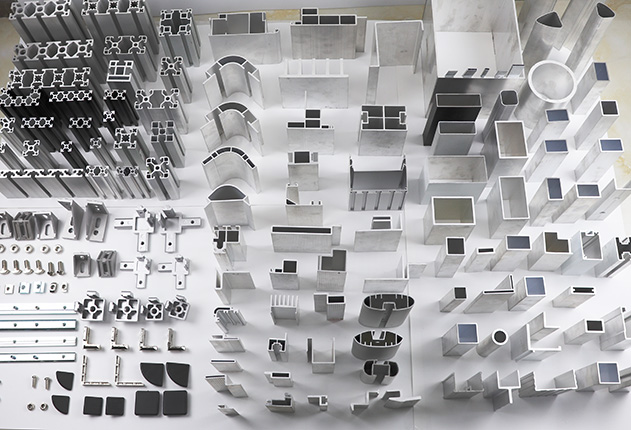

3. Application Fields

Large-tonnage extrusion machines like the 15,000-ton press are widely used in:

Rail Transit Industry: Production of large aluminum structural components for subway cars, light rail vehicles, and high-speed trains.

Aerospace: Manufacturing aircraft structural parts requiring high strength and precision.

Construction and Bridges: Fabrication of architectural curtain walls, bridge components, and modular construction profiles.

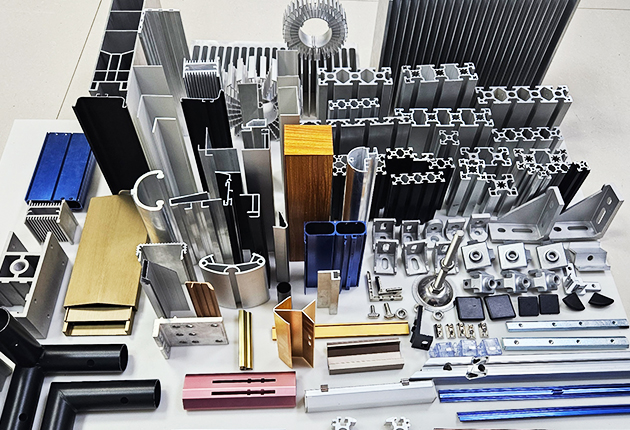

Machinery and Automation: Production of high-load structural aluminum profiles for automated production lines and equipment frames.

4. Support for Customized Production

Using a 15,000-ton extrusion press allows aluminum profile manufacturers to meet a wide variety of customized demands, such as:

Special structural profiles with large wall thicknesses and complex geometries.

High-precision and high-surface-quality profiles.

Custom-cut length and surface treatment based on customer needs.