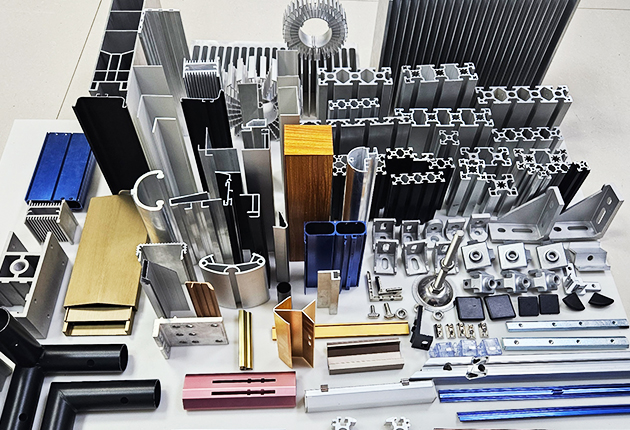

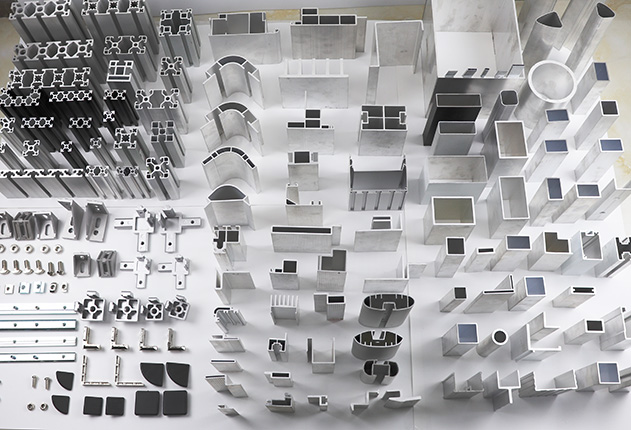

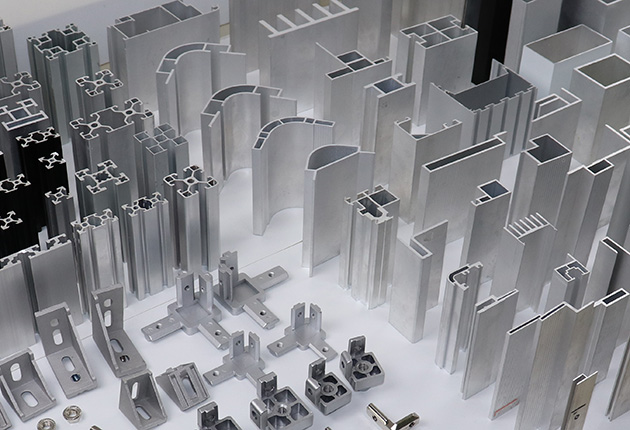

Aluminum extrusion is a process that shapes aluminum alloys through a die, enabling the production of profiles with complex cross-sections and designs. With additional machining and surface finishing, aluminum extrusion parts are widely used in automotive, electronics, industrial, and construction sectors, making them a key material in modern manufacturing.

Lightweight: Only one-third the weight of steel, reducing overall structure weight.

High Strength & Corrosion Resistance: Alloys such as 6061 and 6063 offer both durability and strength.

Design Flexibility: Capable of producing complex geometries tailored to customer requirements.

Versatile Surface Finishes: Anodizing, powder coating, and electrophoresis for both aesthetics and functionality.

Automotive Industry: Body structures, radiators, and brackets.

Electronics & Electrical: Heat sinks, housings, and connectors.

Industrial Machinery: Frames, rails, and supports.

Construction: Window frames and decorative trims.

The precision of aluminum extrusion parts relies on advanced die design and strict production control. Dimensional tolerances, surface quality, and mechanical properties are carefully inspected to ensure consistency and reliability. CNC machining and surface finishing further enhance accuracy and appearance.

As a professional aluminum extrusion factory, we provide customized solutions based on customer drawings or samples. From alloy selection and die development to CNC machining and surface finishing, we are committed to delivering high-quality, reliable aluminum extrusion parts that meet diverse application needs.