In modern electronics, lighting, and industrial applications, heat sinks are essential components to ensure stable device performance. The choice of material directly affects cooling efficiency and product lifespan. Among all materials, aluminum stands out as the preferred option for manufacturing heat sinks.

Excellent Thermal Conductivity of Aluminum

Efficient heat transfer is crucial to prevent components from overheating. Aluminum has a thermal conductivity of about 200 W/m·K. Although slightly lower than copper, it is significantly higher than most metals and plastics. This allows aluminum to quickly transfer heat from the source to the heat sink surface, where it dissipates into the surrounding air.

Lightweight Advantage

Weight is an important factor in heat sink design. Aluminum has a density of only 2.7 g/cm³, which is about one-third that of copper. Its lightweight nature reduces transportation and installation costs, making it widely used in weight-sensitive industries such as automotive, aerospace, and portable electronics.

Excellent Corrosion Resistance

Aluminum naturally forms a dense oxide layer on its surface, providing strong protection against oxidation and corrosion. This property ensures that aluminum heat sinks maintain stable performance and a long service life, even in humid or harsh environments.

Easy Processing and Suitable for Mass Production

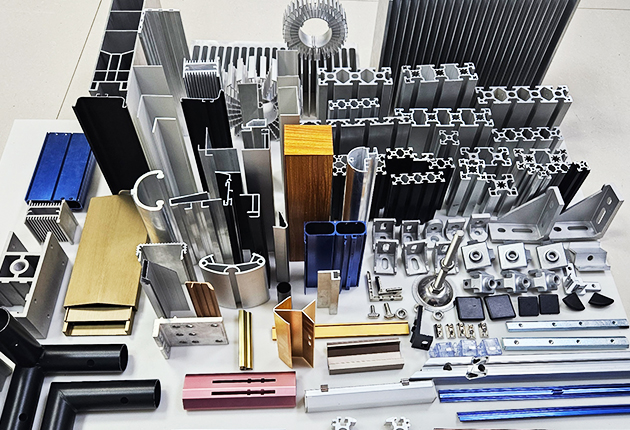

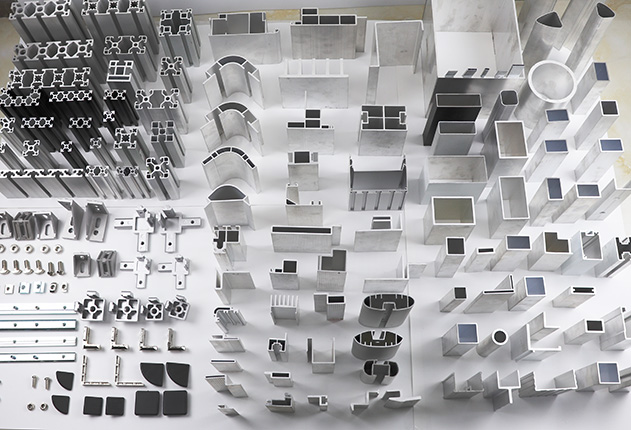

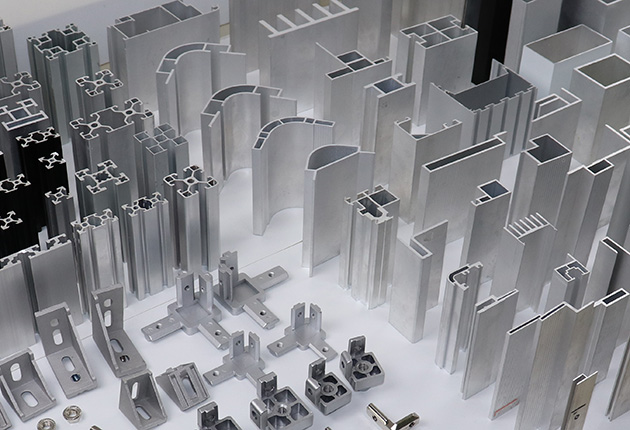

Aluminum can be shaped through extrusion, CNC machining, anodizing, and other processes. Its ductility and plasticity allow designers to create complex fin structures that enhance heat dissipation. This makes aluminum highly adaptable for both standard and customized heat sink

Cost-Effectiveness of Aluminum Heat Sinks

Compared to copper, which offers higher thermal conductivity but comes at a much higher price, aluminum achieves an ideal balance between performance and cost. This makes it the most economical choice for large-scale production and widespread industrial applications.

Typical Applications of Aluminum Heat Sinks

Electronics: computer processors, power modules

LED lighting: prevents overheating and extends lifespan

New energy equipment: EV batteries and control modules

Industrial machinery: inverters, generators, and more

Conclusion

With its excellent thermal conductivity, lightweight nature, corrosion resistance, easy processing, and cost-effectiveness, aluminum has become the dominant material in heat sink manufacturing. As electronics and new energy industries continue to expand, the demand and applications for aluminum heat sinks will grow even further.

Telephone number: +86 15093222866

Whatsapp:+86 15093222866

Email: huayangalu@gmail.com