Classification of Aluminum Profiles: Standard Profiles and Custom-Made Profiles

2025-08-11

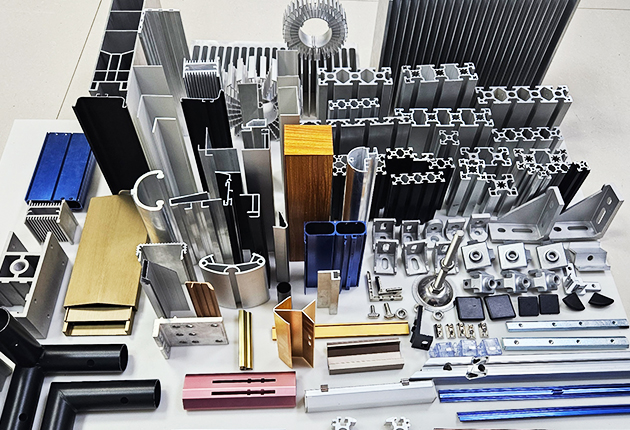

Overview of Aluminum Profile Classification

Aluminum profiles are widely used in industrial manufacturing, construction, transportation, and household products due to their light weight, high strength, corrosion resistance, and excellent machinability. Based on cross-sectional shape and production method, aluminum profiles can be generally divided into standard aluminum profiles and custom-made aluminum profiles.

1. Standard Aluminum Profiles

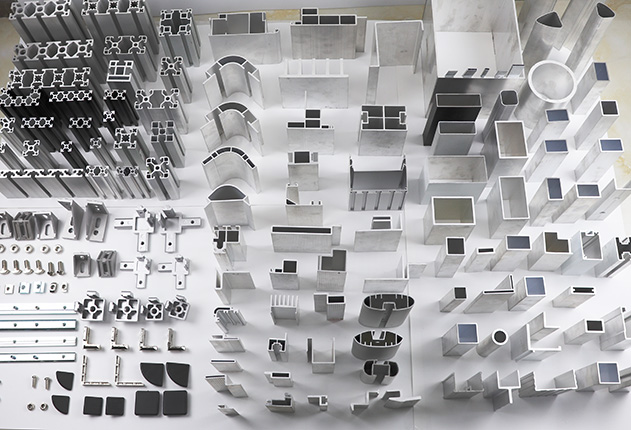

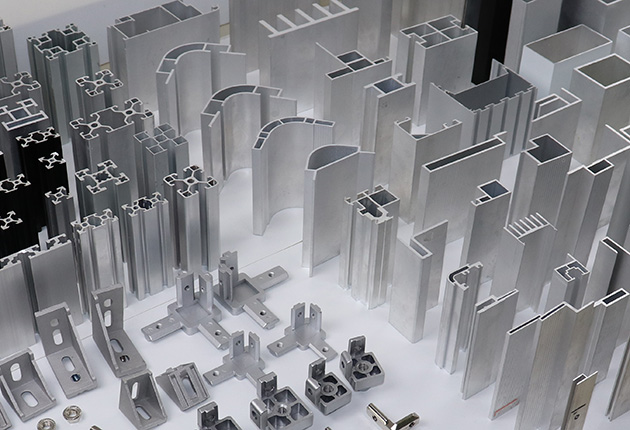

Standard aluminum profiles refer to profiles with fixed cross-sectional dimensions and shapes, typically produced according to industry or enterprise standards. These profiles often have shapes such as H, U, T, square, or round, with standardized sizes suitable for versatile structural and assembly applications.

Key Features:

Standardized production: Mass-produced with short lead times.

High versatility: Fits a wide range of structural designs.

Lower cost: No additional mold-opening fees required.

Common Applications:

Industrial framework structures

Conveyor systems

Machine frames and supports

Doors, windows, and partition systems

2. Custom-Made Aluminum Profiles

Custom-made aluminum profiles are designed, molded, and extruded based on the client’s specific project requirements. These profiles can be tailored in terms of cross-sectional shape, dimensions, wall thickness, and surface treatment to ensure optimal structural and functional performance.

Key Features:

Personalized design: Cross-sectional shapes fully customized to project needs.

Special functionality: Optimized for load-bearing, aesthetics, or installation requirements.

High-precision machining: Compatible with CNC machining, anodizing, powder coating, and other finishes.

Typical Use Cases:

Hand trolleys: Designed with specific thickness and joint structures for load capacity.

Luggage handles: Lightweight yet high-strength profiles tailored for mobility products.

Special machinery: Profiles with customized mounting holes and reinforced structures.

3. Tips for Choosing the Right Aluminum Profile

1.Match the profile type to the application: Standard profiles are ideal for fast assembly and general structures; custom profiles are best for unique designs with specific technical requirements.

2.Balance cost and lead time: Standard profiles are cost-effective and available immediately; custom profiles require mold opening and longer production times.

3.Select the right surface treatment: Choose anodizing, powder coating, or electrophoresis based on corrosion resistance, appearance, and environmental conditions.

Why Choose Henan Huayang Aluminum

Henan Huayang Aluminum, equipped with a 15,000-ton extrusion press, CNC precision machining facilities, and multiple surface treatment lines, provides both mass production of standard profiles and high-precision custom profile manufacturing. We serve diverse industries, from construction to specialized industrial equipment.

Telephone number: +86 15093222866

Whatsapp:+86 15093222866

Email: huayangalu@gmail.com