1. Background & Industry Trends

Aluminum profiles have become key structural materials in modern rail transit systems across the globe. With their lightweight and energy-efficient properties, they represent a growing trend toward sustainable and high-performance transportation infrastructure.

2. Material Advantages

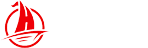

Lightweight & High Strength: Using 6000-series alloys (e.g., 6063, 6061, 6005A), aluminum profiles reduce the weight of train cars by 30–40% compared to steel, enhancing energy efficiency and minimizing rail pressure.

Excellent Corrosion Resistance: Natural oxide layers and surface treatments like anodizing and powder coating help aluminum resist harsh outdoor and urban environments, reducing long-term maintenance costs.

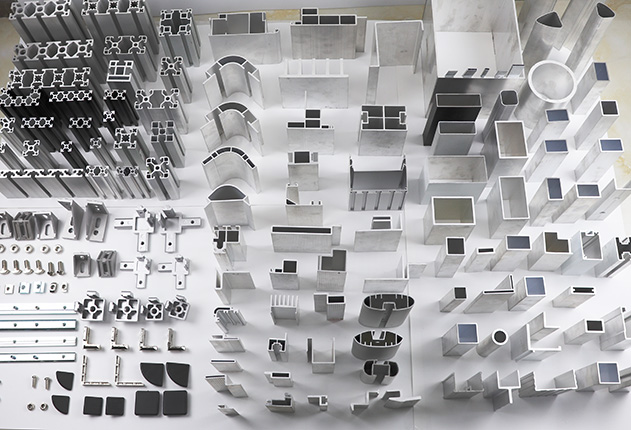

Ease of Processing: Aluminum profiles support deep processing such as cutting, welding, and bending, making them ideal for custom components including guide rails, body frames, and window frames.

3. Application Scenarios

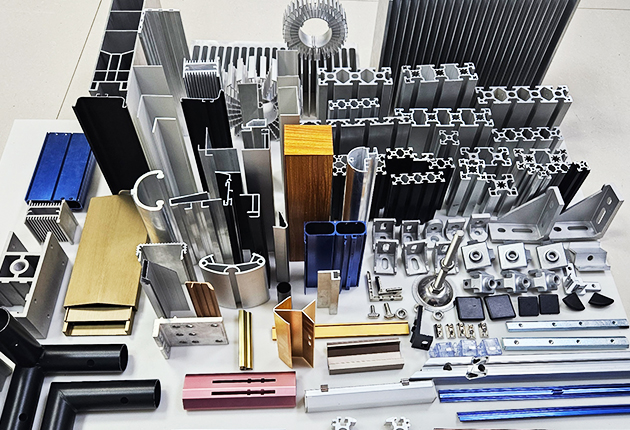

Train Body Structures: Aluminum is widely used for metro and high-speed train body frames, floor structures, and safety support systems.

Interior Components: Ceiling frames, luggage racks, seat supports, and electric cable ducts are often made of custom aluminum profiles.

Track and Station Parts: Aluminum is used for platform screen door frames, guide rails, and safety barriers in stations.

4. Industry Case Studies

Nanning Metro Line 1 used 25 custom aluminum profiles from Nannan Aluminum for critical body components.

Conglin Aluminum provided solutions for major metro systems in Shanghai, Wuhan, Hangzhou, Guangzhou, and even Seoul, South Korea.

5. Comparison With Other Materials

Versus Steel: Aluminum is lighter, does not rust, and requires less frequent maintenance, resulting in lower lifecycle costs.

Versus Plastics/Composites: Aluminum offers superior mechanical strength and dimensional stability while being 100% recyclable.

6. Conclusion & Recommendations

Aluminum profiles are ideal materials for metro and rail applications due to their structural performance and durability. For best results, select profiles with standard wall thickness (typically 2.0 mm+), appropriate alloy grades, and weather-resistant surface treatments to ensure safe, long-term use in transit infrastructure.