The superior user experience and long product lifespan offered by aluminum profiles make them an indispensable and ideal material for modern high-quality baby strollers.

I. Application of Aluminum Profiles in Baby Strollers

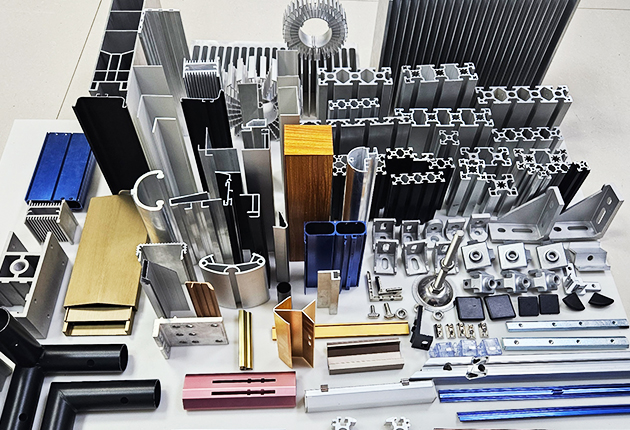

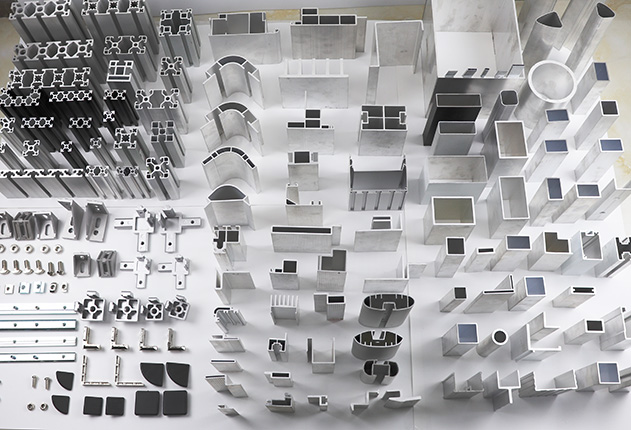

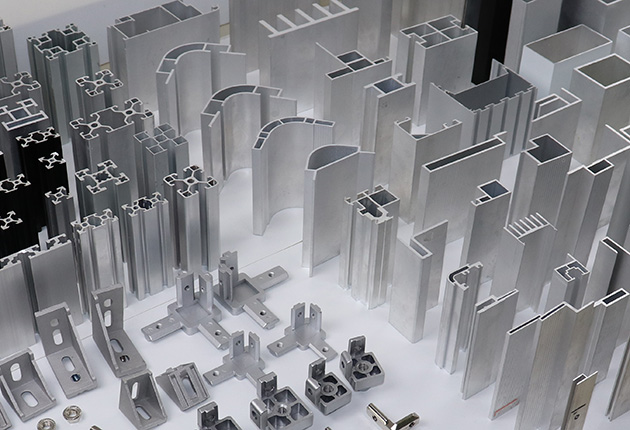

Aluminum profiles are primarily manufactured through extrusion molding. They can be made into tubes or components with various complex cross-sectional shapes according to design needs. They are mainly used in the following parts of the stroller:

Main Frame: This is the most crucial application. Including the push rod, chassis frame, front and rear supports, etc., it forms the "skeleton" of the stroller, determining the overall stability and load-bearing capacity.

Wheel Brackets: The part connecting the wheels to the main body, requiring good strength and impact resistance.

Joint Connectors: High-strength aluminum profiles are used in key areas such as folding mechanisms to ensure reliable connections and smooth operation.

Accessory Brackets: Such as cup holders, shopping basket support frames, etc.

By using aluminum profiles of different thicknesses, diameters, and alloy formulations, manufacturers can achieve lightweight and aesthetically pleasing designs while ensuring strength.

II. Core Advantages of Aluminum Profiles

The reason aluminum profiles are the preferred choice for high-end strollers is primarily due to the following outstanding advantages:

1. Lightweight: Using aluminum profiles significantly reduces the overall weight of the stroller, making it easier and less strenuous for parents to lift, fold, climb stairs, or put in the trunk with one hand.

2. Safety: Aluminum alloys, especially the commonly used 6000 series (such as 6061 and 6063) and 7000 series, have a high strength-to-weight ratio after heat treatment (T6 state). This means it can withstand the weight of a baby and various impacts from daily use (such as bumpy roads and occasional collisions), while ensuring the frame is not easily bent or deformed, ensuring the baby's safety and the product's durability.

3. Long Service Life: Aluminum naturally forms a dense oxide film on its surface, giving it excellent rust resistance. This is crucial for strollers frequently used outdoors, potentially exposed to rain, mud, or humid sea air, ensuring the product remains like new for a long time and reducing maintenance hassles.

4. Processability and Aesthetics: Extrusion molding allows aluminum profiles to be easily crafted into various streamlined, ergonomically designed complex cross-sections, resulting in both aesthetic appeal and optimized structural strength.

5. Diverse Surface Treatments: Aluminum is well-suited for a variety of surface treatments, such as anodizing (available in silver, champagne gold, deep black, pink, and more), sandblasting, and electrophoretic coating. These treatments not only give the stroller a stylish and attractive appearance but also further enhance its surface hardness, wear resistance, and corrosion resistance.

6. Environmental Friendliness and Recyclability: Aluminum is a 100% recyclable metal, requiring only 5% of the energy needed to remelt it. Using aluminum profiles aligns with modern families' demands for environmental protection and sustainable development.

The application of aluminum profiles in baby strollers perfectly balances the three core requirements of "lightweight," "sturdy," and "aesthetically pleasing." It makes caring for your baby easier for parents while ensuring the baby's safety and comfort during outings.

.png)