1. Background & Challenge

In the fast-evolving world of robotics, chassis design plays a critical role in determining agility, speed, and stability.

The FIM Swerve X2i Bundle, designed for FIRST Robotics competitions, places extremely high demands on its chassis:

1.Must be lightweight to increase speed

2.Must be high-strength to support drive modules and sensors

3.Must allow easy installation and maintenance to adapt to rapid adjustments during competitions

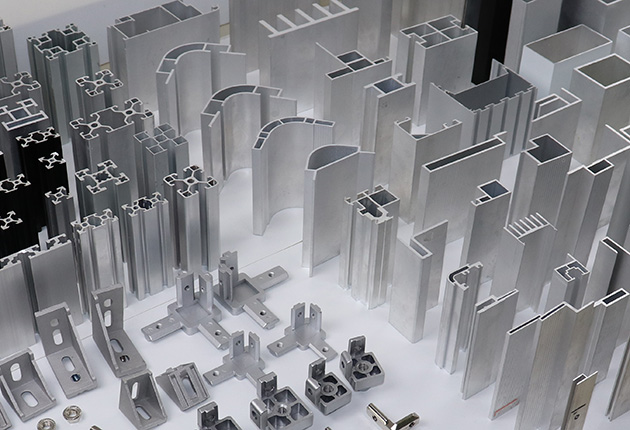

2. Material Selection

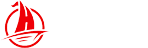

For the chassis frame of the robot kit, the U.S. client selected our punched aluminum square tubes.

Advantages of punched aluminum square tubes:

1.Lightweight – reduces overall weight, improving acceleration and agility

2.High strength – premium aluminum alloy ensures structural stability

3.Corrosion resistance – suitable for various competition environments

4.Multi-hole design – pre-punched holes reduce machining time and improve assembly efficiency

3. Application Process

The punched aluminum square tubes were used as the structural frame to mount key components of the FIM Swerve X2i:

1.Drive Modules – WCP Swerve X2i, enabling omnidirectional movement

2.Sensors – CTR Electronics CANcoders, for precise steering control

3.Expansion Components – flexible mounting points for different mission setups

4. Results

With our punched aluminum square tubes, the client achieved:

1.Significant reduction in total chassis weight

2.Structural strength to withstand high-speed competitive play

3.Reduced assembly and maintenance time

4.Faster and more precise omnidirectional movement during competitions

5. Conclusion

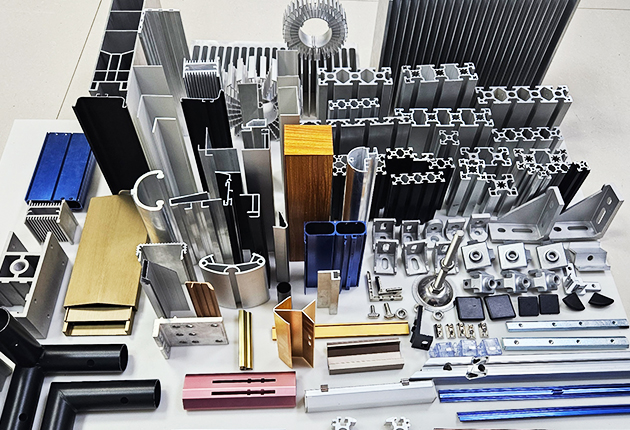

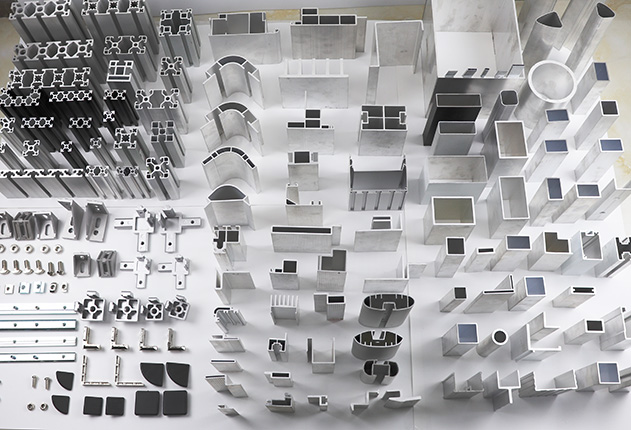

This case study demonstrates the versatile value of aluminum profiles in robotics manufacturing.

Thanks to their lightweight, high strength, and flexible assembly capabilities, our punched aluminum square tubes helped the client build a high-performance competition robot chassis, providing strong technical support for the FIRST Robotics challenge.