In modern industrial applications, aluminum profiles are widely used in construction, transportation, electronics, and machinery due to their light weight, high strength, and excellent corrosion resistance. As an aluminum profile manufacturer, we understand the high importance our customers place on product quality. Therefore, we always adhere to strict production processes and quality control standards to ensure that every batch of products meets high requirements and satisfies our customers' actual needs.

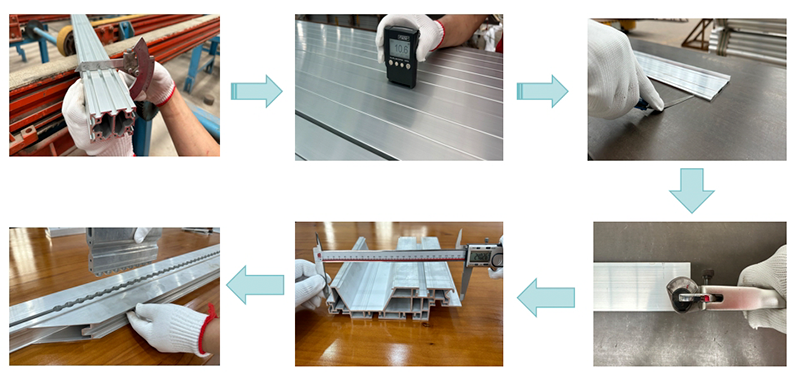

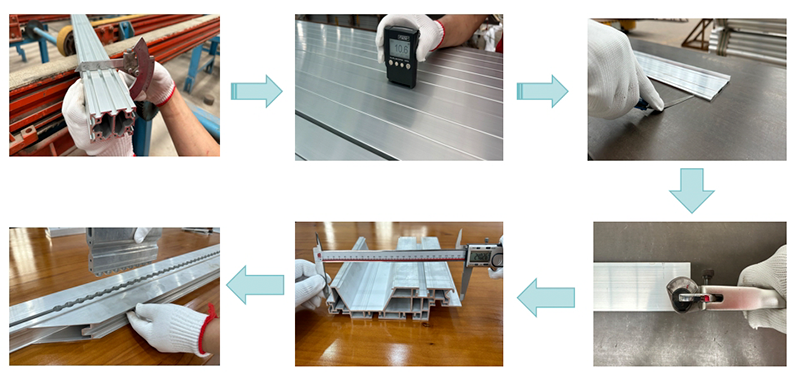

Aluminum Profile Production Process Overview

The production process of aluminum profiles involves several key steps, each of which plays a crucial role in ensuring the final product's exceptional quality. From material selection to the final inspection, every step is rigorously controlled to ensure that every aluminum profile we deliver meets our customers' high standards.

1.Material Selection

We use high-quality aluminum alloys to ensure that the aluminum profiles possess the required strength and corrosion resistance. All materials are rigorously tested and certified to meet international standards.

2.Extrusion Process

The extrusion process is the core of aluminum profile production. Using advanced extrusion equipment, we shape aluminum alloys through heating and pressurization according to the design specifications. During the extrusion process, we strictly control parameters such as temperature and pressure to ensure the dimensional accuracy and surface quality of the aluminum profiles.

3.Surface Treatment

We offer a variety of surface treatment options such as anodizing, spraying, and brushing. These treatments not only enhance the aesthetics of the aluminum profiles but also improve their corrosion resistance, ensuring that the products remain durable over time.

Quality Control Standards

To ensure that every batch of aluminum profiles meets high standards, we have established a rigorous quality control process. Each stage of production undergoes meticulous inspection to prevent any defective products from reaching the market.

1.ISO Certification

We are ISO 9001 certified and adhere to international standards in our production management. Every production step is carried out under strict quality control, ensuring that every aluminum profile, from raw material to finished product, meets industry standards.

2.Inspection During Production

We perform comprehensive quality checks at each stage of the aluminum profile production process. From material inspection upon arrival to dimensional checks during production, and final product testing, we ensure that every batch of aluminum profiles is consistent and reliable.

3.Finished Product Testing

Every aluminum profile undergoes a series of tests, including tensile tests, hardness tests, and corrosion resistance tests, to ensure that the final products meet customer requirements and industry standards.

Customer Benefits and Assurance

Through strict quality control and meticulous production processes, we not only ensure the stability and durability of our aluminum profiles but also enhance their competitiveness in the market. Our aluminum profiles help customers reduce maintenance costs and improve the long-term stability of their projects.

We believe that quality is the foundation of building long-term relationships with our customers. By rigorously inspecting every batch of aluminum profiles, we provide our clients with more reliable solutions. Whether for large-scale construction projects or precision machinery, our aluminum profiles meet high standards and offer lasting value to our customers.

Conclusion

In the aluminum profile production process, every employee is guided by the needs of our customers, ensuring that every product is made to perfection. We firmly believe that only through stringent quality management and continuous technological innovation can we maintain an edge in a competitive market.

We invite customers to contact us to learn more about our aluminum profile production processes and quality control standards, or to arrange an on-site visit. We will continue to uphold our commitment to "quality first" and provide high-quality aluminum profile products to help our customers succeed.