Introduction

Aluminum profiles, as a widely used lightweight material, have become an indispensable part of various industries. Especially in sectors such as construction, transportation, electronics, and machinery manufacturing, the demand for aluminum profiles is growing rapidly. Through the aluminum extrusion process, aluminum materials can be shaped into profiles with different forms to meet specific application needs. In recent years, the demand for custom aluminum profiles has been rising steadily. This article explores the basic principles of aluminum profiles, the aluminum extrusion process, and the application prospects of custom aluminum profiles in various industries.

What are Aluminum Profiles and Aluminum Extrusion Technology?

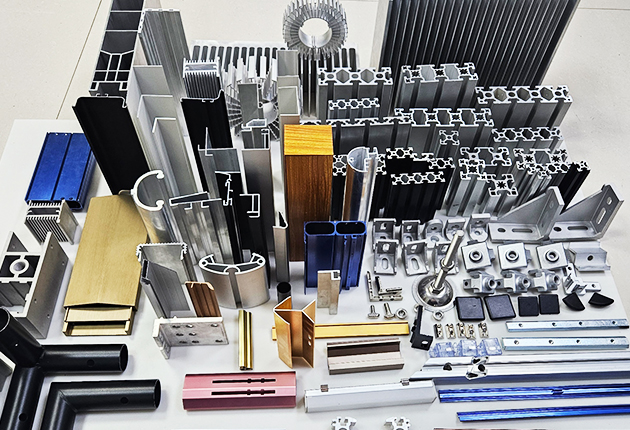

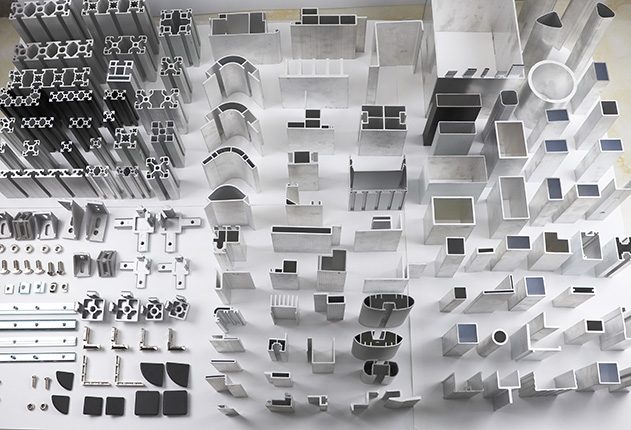

Aluminum profiles are various cross-sectional shapes made by processing aluminum alloy materials through the aluminum extrusion process, which involves heating the aluminum at high temperatures and applying pressure. Aluminum profiles are widely used in industrial and commercial projects, including frame structures, windows, building facades, transportation vehicles, and more.Aluminum extrusion technology is a process that involves forcing aluminum material through a die under high pressure to create various shapes. Aluminum extrusion not only provides highly customized sizes and forms but also ensures high precision and excellent mechanical properties in the final product.

Advantages of Custom Aluminum Profiles

1.Precise Sizes and Shapes

Through aluminum extrusion, custom aluminum profiles can be made with precision down to the micrometer level, ensuring they meet the requirements of various complex structures. Whether it's for industrial equipment casings or building materials, custom aluminum profiles offer perfect solutions for customers.

2.Lightweight with High Strength

Aluminum alloys are naturally corrosion-resistant and lightweight, offering high strength. Custom aluminum profiles can significantly reduce weight while maintaining structural integrity, thus lowering transportation costs.

3. Energy-Efficient and Environmentally Friendly

Aluminum profiles are recyclable, making them an environmentally friendly material. Waste generated during the aluminum extrusion process can also be recycled, reducing resource wastage. Highly Malleable Custom aluminum profiles offer versatility not only in size and shape but also in surface treatments such as anodizing, powder coating, etc., which enhance their aesthetic appeal and durability, adapting to various application needs.

Industry Applications of Custom Aluminum Profiles

1.Construction Industry

In the construction industry, aluminum profiles are widely used in window frames, curtain walls, balcony railings, and more. The lightweight nature of aluminum makes it an ideal choice for modern architecture. Additionally, aluminum profiles are used in building facades, providing enhanced aesthetics and wind pressure resistance.

2.Transportation

In the manufacturing of automobiles, trains, and aircraft, aluminum profiles are commonly used in body structures, interior fittings, and frames. The lightweight characteristic of aluminum helps reduce fuel consumption and carbon dioxide emissions, promoting the development of sustainable transportation.

3.Electronics and Electrical Industry

Custom aluminum profiles are widely used in the casings, heat dissipation systems, and mechanical frames of electronic devices. Due to their excellent heat dissipation properties, many high-performance electronic devices and LED lighting systems utilize aluminum profiles to ensure long-term stable operation.

4.Machinery Manufacturing

In machinery manufacturing, aluminum profiles are widely used in robots, automation equipment, conveyor systems, and more. Custom aluminum profiles can be tailored to the design requirements of equipment, offering unique structural forms and improving production efficiency.

Future Trends in Aluminum Profiles

With ongoing technological advancements, aluminum extrusion processes will continue to improve, increasing the precision and production efficiency of aluminum profiles. Additionally, stricter environmental regulations are driving the demand for aluminum profiles, particularly in sectors like green construction and smart manufacturing, where custom aluminum profiles will play an increasingly significant role.

1.Intelligent Customization

With the development of artificial intelligence and big data technologies, the customization of aluminum profiles will become more intelligent. By utilizing precise market demand analysis and automated production lines, the production of aluminum profiles will become more flexible and faster, meeting customers' personalized needs.

2.Green Aluminum Profiles

Environmental requirements are prompting aluminum profile manufacturers to focus more on energy-saving, reducing emissions, and recycling resources in the production process. In the future, the production of aluminum profiles will focus more on eco-friendliness, low carbon emissions, and sustainability.

Conclusion

As a high-performance, widely applicable material, aluminum profiles have found extensive use across various industries. The continuous innovation of aluminum extrusion technology provides higher precision and broader application scenarios for custom aluminum profiles. As the demand for custom aluminum profiles increases, the industry will continue to evolve towards greater diversification, efficiency, and environmental sustainability, offering more solutions for industries across the board. If you are looking for custom aluminum profiles or are interested in learning more about aluminum extrusion technology, feel free to contact us for professional technical support and industry solutions.

.jpg)