The effects of different extrusion ratios on the microstructure and mechanical properties of 6063 aluminum alloy were analyzed when the billet size, ingot heating temperature and extrusion speed remained unchanged. The results show that dynamic recrystallization occurs during the extrusion process, and the microstructure is composed of equiaxial recrystallization grains and a strong <100> silk texture is formed under the condition of high extrusion ratio. The mechanical properties of the alloy increase with the increase of the extrusion ratio. When the extrusion ratio is 156, the tensile strength and elongation of the alloy reach the maximum value, which are 228 MPa and 26.9%, respectively. The fracture structure is composed of a large number of equiaxial dimples, and the fracture mechanism changes from brittle fracture to ductile fracture.

6063 aluminum alloy belongs to the low alloying Al-Mg-Si series of heat-treatable aluminum alloys, which has excellent extrusion forming properties, good corrosion resistance and comprehensive mechanical properties, and is widely used in the automotive industry because of its easy oxidation and coloring [1-2]. With the acceleration of the automotive lightweight trend, the application of 6063 aluminum alloy extrusion material in the automotive industry has also further increased.

The microstructure and properties of extruded materials are affected by extrusion speed, extrusion temperature and extrusion ratio. The extrusion ratio is mainly determined by extrusion pressure, production efficiency and production equipment. When the extrusion ratio is small, the deformation degree of alloy is small, and the microstructure is not obvious. By increasing the extrusion ratio, the grain can be refined significantly, the coarse second phase can be broken, the uniform structure can be obtained, and the mechanical properties of the alloy can be improved.

The dynamic recrystallization of 6061[3] and 6063[4] aluminum alloys occurs during the extrusion process. When the extrusion temperature is constant, the tensile strength and elongation of the alloys increase with the increase of the extrusion ratio, the grain size decreases, and the strengthening phase is fine and dispersed. However, with the increase of the extrusion ratio, the extrusion pressure required in the extrusion process also increases, resulting in greater thermal effect, which increases the internal temperature of the alloy and reduces the performance of the product. The effects of extrusion ratio, especially high extrusion ratio on the microstructure and mechanical properties of 6063 aluminum alloy were studied.

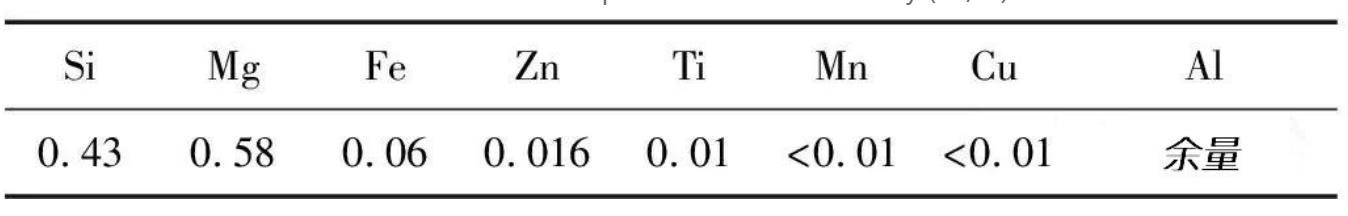

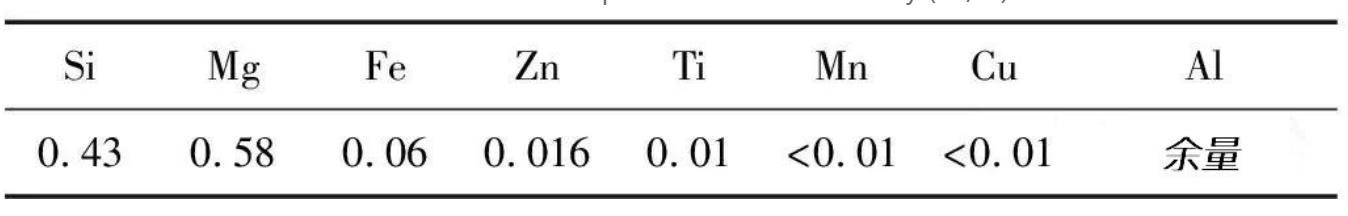

The test material is 6063 aluminum alloy, and the chemical composition is shown in Table 1. The original size of the ingot was Φ55 mm×165 mm, and after homogenization at 560 ℃ for 6 h, the extrusion billet was processed into Φ50 mm×150 mm. The billet is heated to 470 ℃ for heat preservation, the preheating temperature of the extrusion cylinder is 420 ℃, and the preheating temperature of the mold is 450 ℃. When the extrusion speed (extrusion rod movement speed)V=5 mm/s remained unchanged, 5 groups of different extrusion ratio tests were carried out, and the extrusion ratio R was 17(corresponding to die hole diameter D=12 mm), 25(D=10 mm), 39(D=8 mm), 69(D=6 mm), 156(D=4 mm), respectively.

After the metallographic sample was sanded and mechanically polished, it was corroded with 40% HF reagent for about 25 s, and the metallographic structure of the sample was observed by LEICA-5000 LEICA optical microscope. A texture analysis sample of 10 mm×10 mm was taken from the center of the longitudinal section of the extruded bar and subjected to mechanical polishing and corrosion to remove the surface stress layer. X 'PERT Pro MRD X-ray diffraction analyzer of PANalytical Company was used to measure the incomplete polar diagram of three crystal face groups of samples {111}, {200} and {220}. X 'PERT Data View and X 'Pert Texture software were used to process and analyze the texture data.

The tensile sample of the as-cast alloy is taken from the center of the ingot. After extrusion, the tensile sample is taken along the extrusion direction. The size of the standard distance area is Φ4 mm×28 mm. The tensile test was carried out by the SANS CMT5105 universal material testing machine with a tensile rate of 2 mm/min. The average values of 3 standard samples were calculated as the mechanical properties data. The fracture morphology of tensile specimens was observed by low power scanning electron microscope (Quanta 2000, FEI, USA).

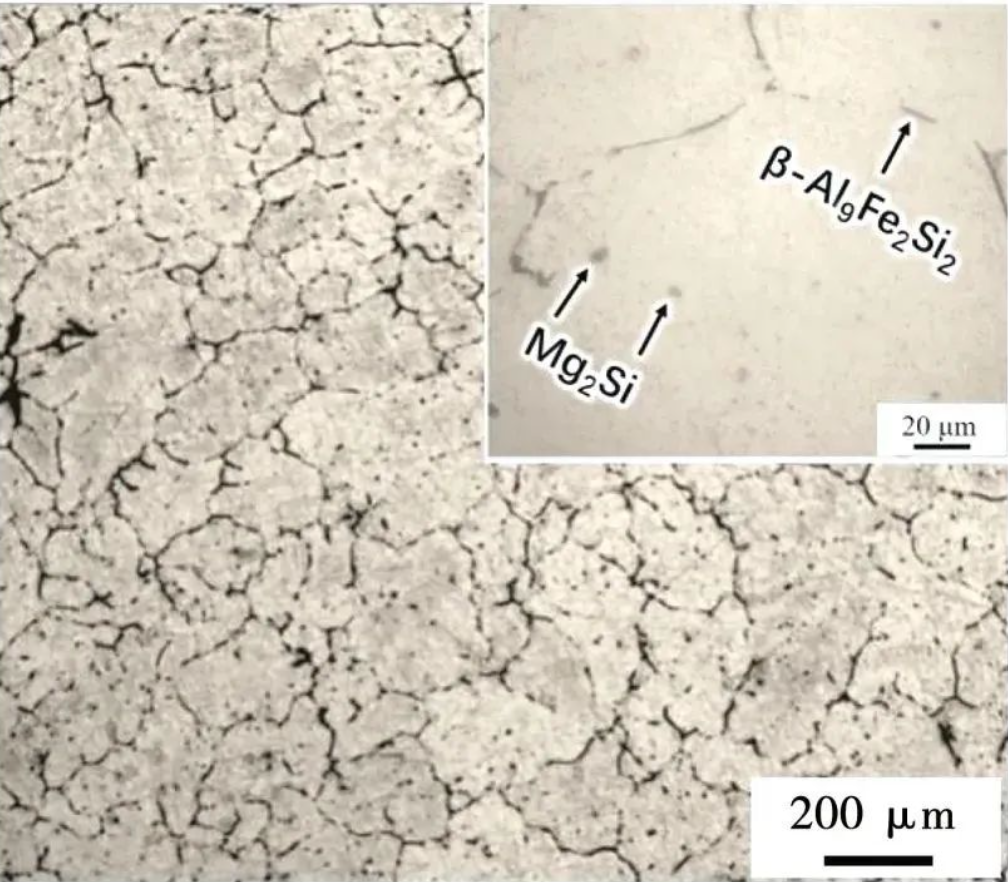

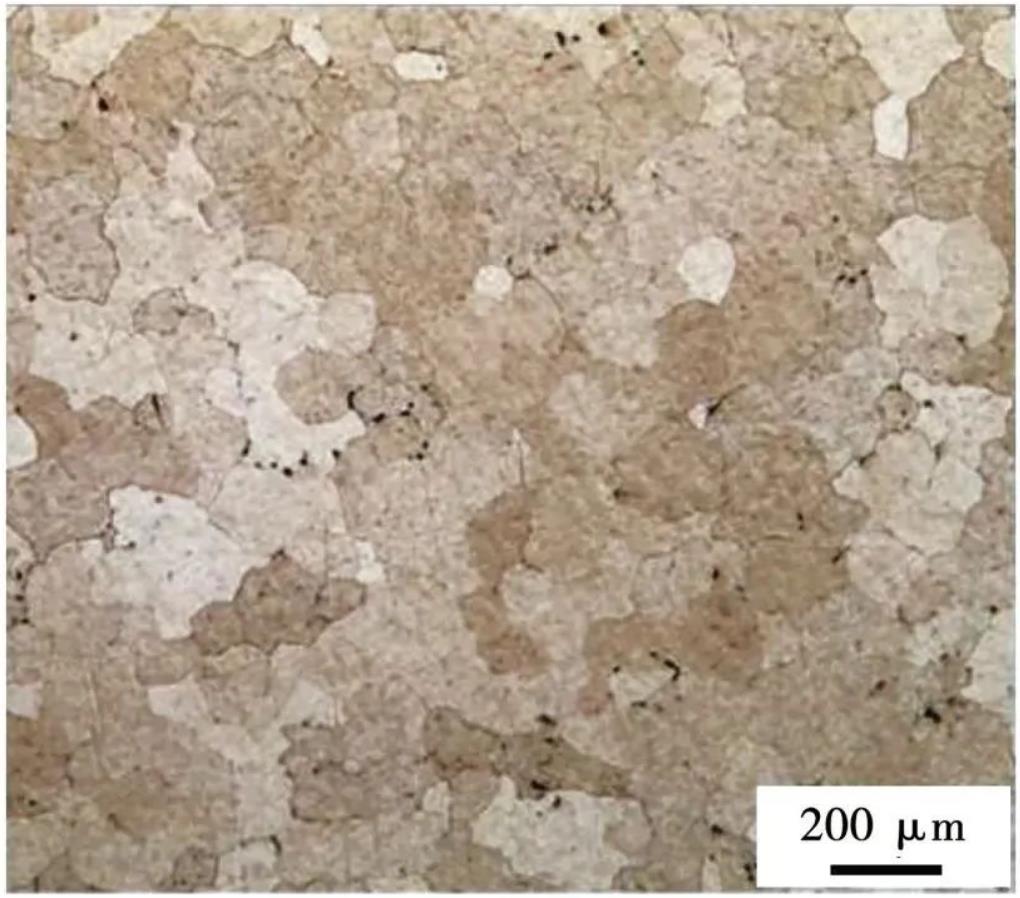

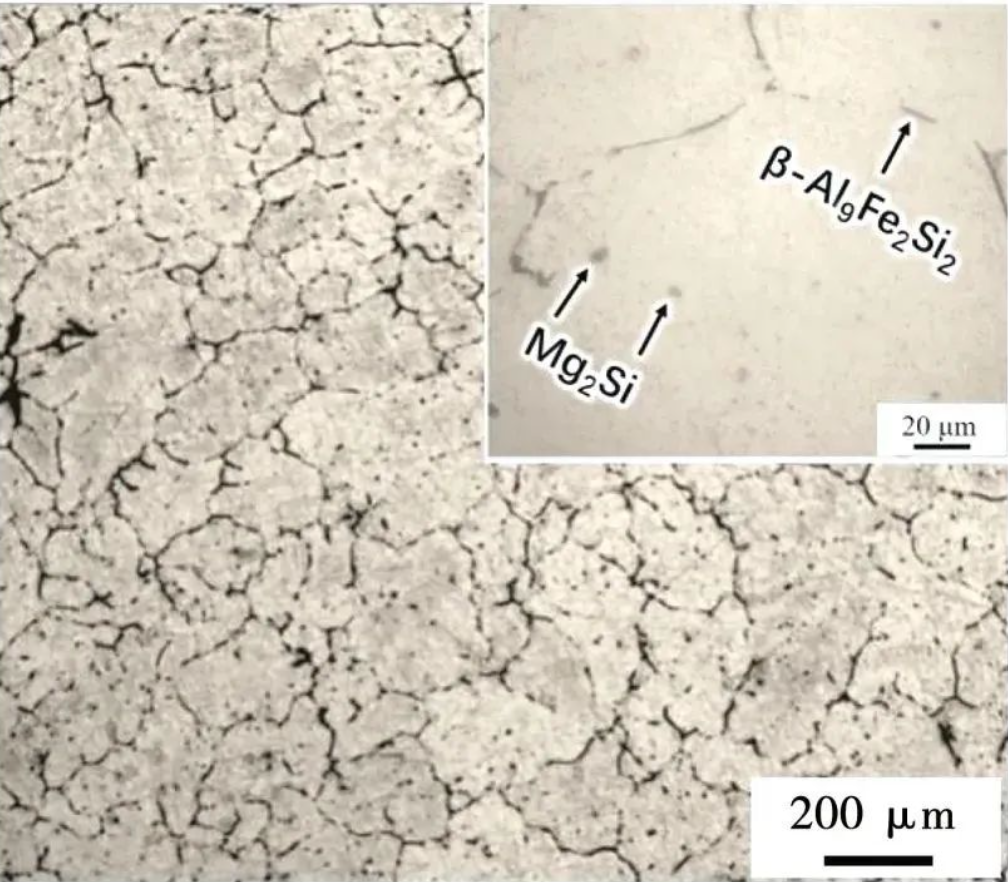

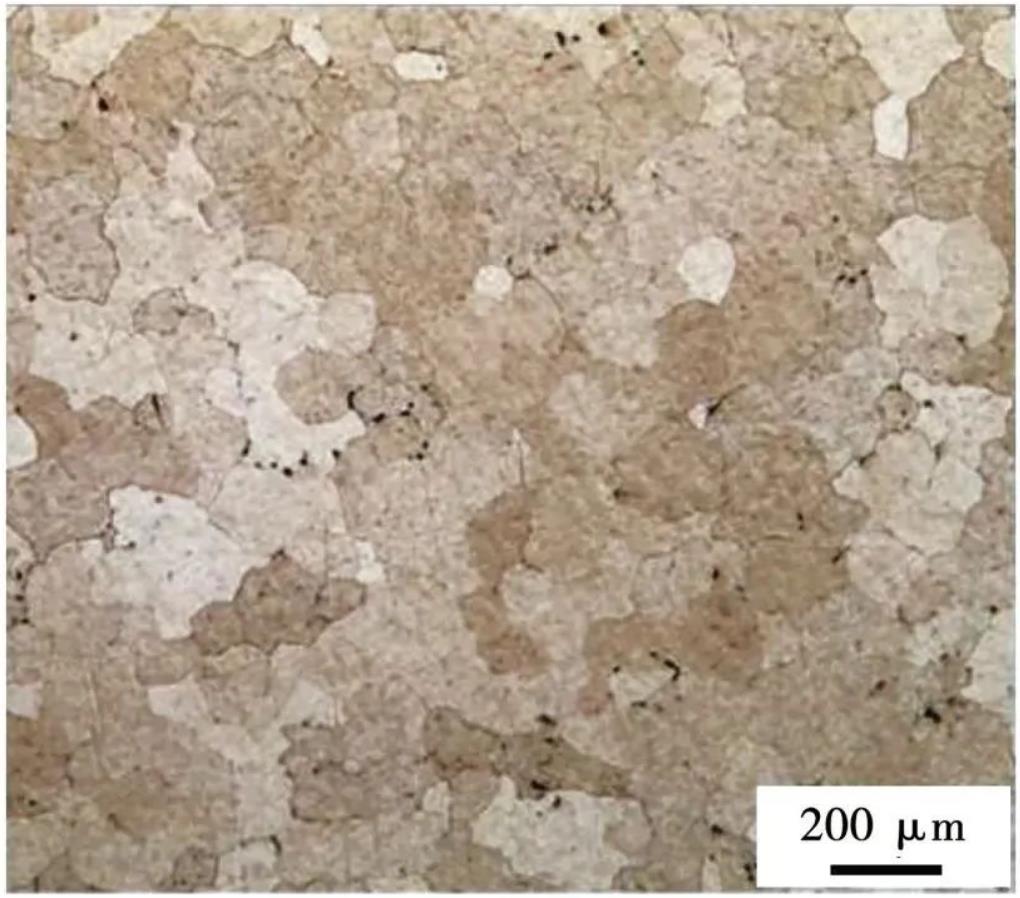

FIG. 1 shows the metallographic photos of 6063 aluminum alloy before and after homogenization. As can be seen from FIG. 1a, α-Al grains in the as-cast structure vary in size, with a large number of mesh β-Al9Fe2Si2 phases gathered at the grain boundaries and a large number of granular Mg2Si phases inside the grains. After the ingot was homogenized at 560 ℃ for 6 h, the non-equilibrium eutectic phase between the alloy dendrites gradually dissolved, and the alloying elements dissolved into the matrix, with uniform microstructure and an average grain size of about 125 μm(FIG. 1b).

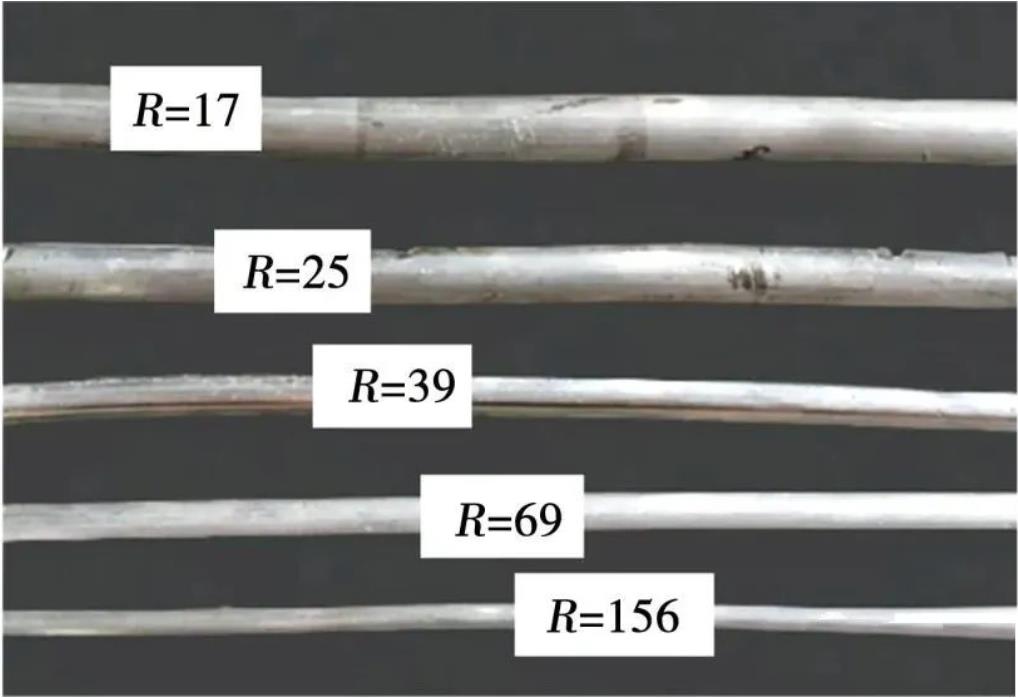

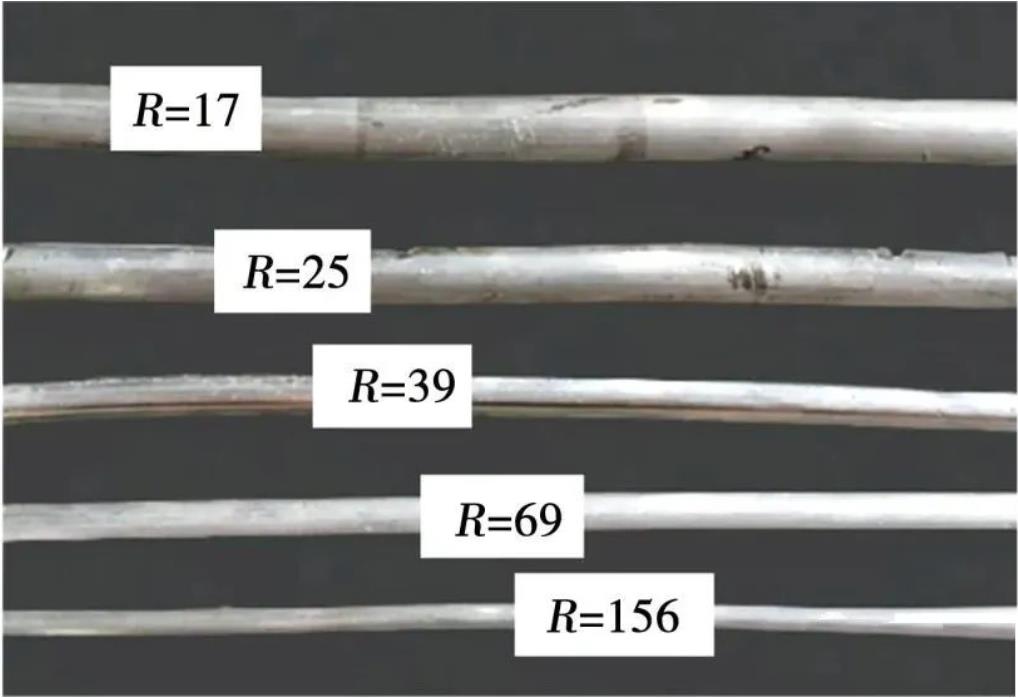

Figure 2 shows the bar appearance of 6063 aluminum alloy with different extrusion ratios. As can be seen from Figure 2, the 6063 aluminum alloy bar with different extrusion ratios has good surface quality, especially when the extrusion ratio increases to 156 (corresponding to the bar extrusion exit speed of 48 m/min), there are still no cracks, peeling and other extrusion defects on the bar surface, indicating that 6063 aluminum alloy also has good hot extrusion forming performance at high speed and large extrusion ratio.

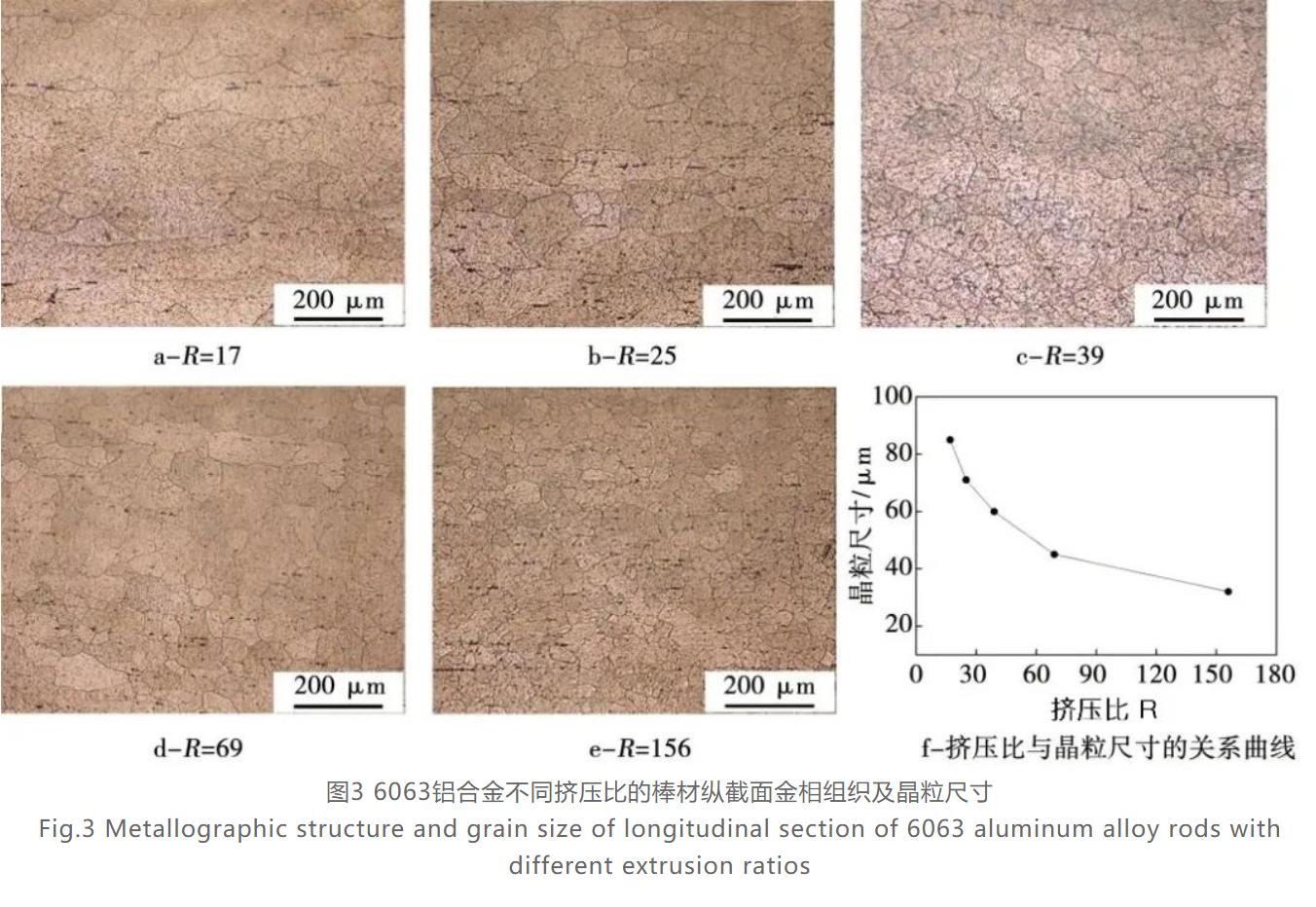

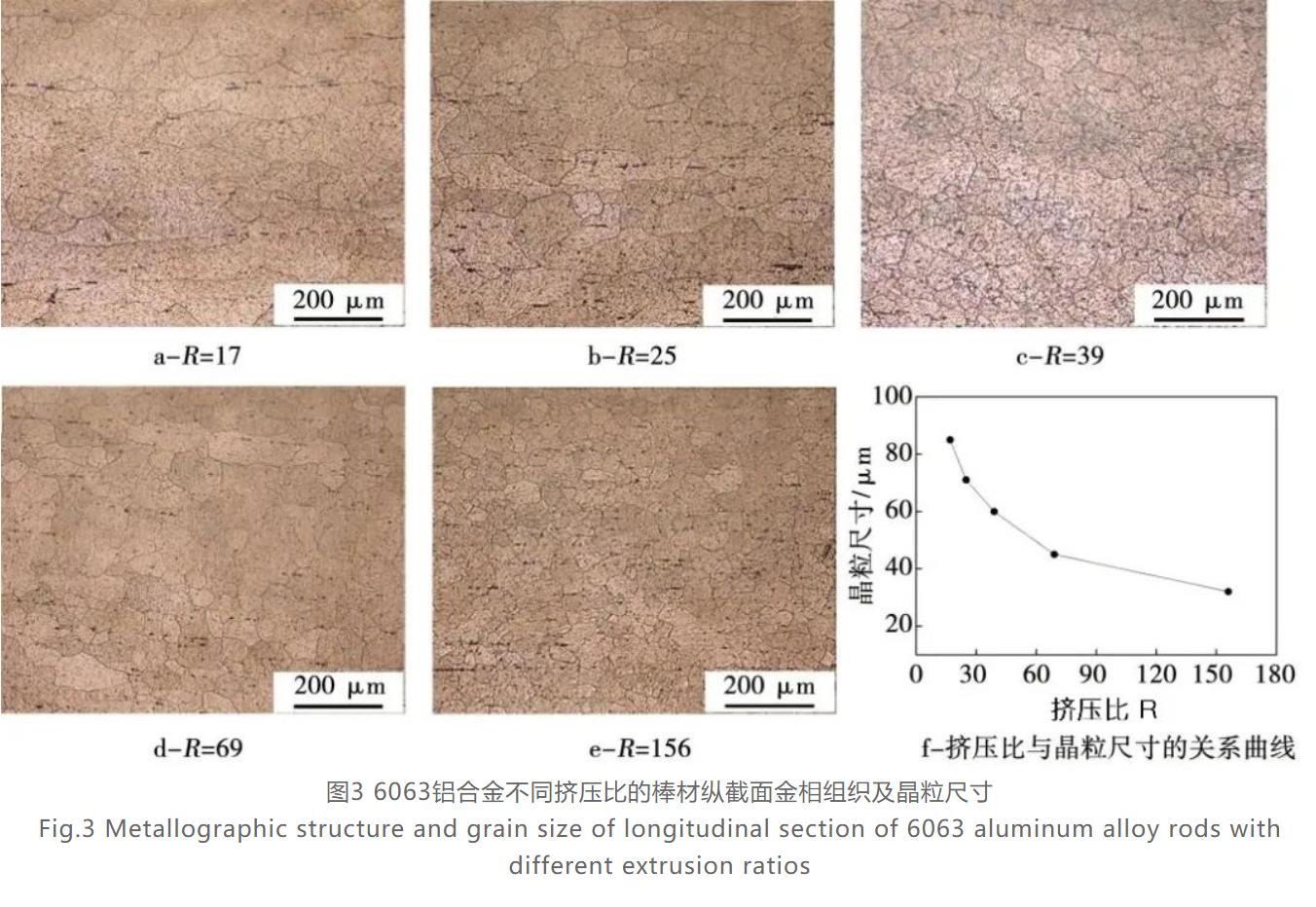

FIG. 3 shows the longitudinal section metallographic microstructure of 6063 aluminum alloy bars with different extrusion ratios. The grain structure of bar with different extrusion ratio is elongated or refined in different degree. When the extrusion ratio is 17, the original grain is elongated along the extrusion direction, accompanied by the formation of a small number of recrystallized grains, but the grains are still relatively coarse, with an average grain size of about 85 μm(FIG. 3a). When the extrusion ratio is 25, the grains are drawn more slender, the number of recrystallized grains increases, and the average grain size decreases to about 71 μm(FIG. 3b). When the extrusion ratio is 39, except for a small number of deformed grains, the microstructure is basically composed of equiaxed recrystallized grains with an average grain size of about 60 μm(FIG. 3c). When the extrusion ratio is 69, the dynamic recrystallization process is basically completed, and the coarse original grains have completely transformed into uniform recrystallization grains, and the average grain size is refined to about 41 μm(FIG. 3d). When the extrusion ratio is 156, the microstructure is more uniform and the grain size is greatly refined to about 32 μm with the full progress of dynamic recrystallization (FIG. 3e). With the increase of the extrusion ratio, the dynamic recrystallization process becomes more complete, the microstructure of the alloy becomes more uniform, and the grain size is obviously refined (FIG. 3f).

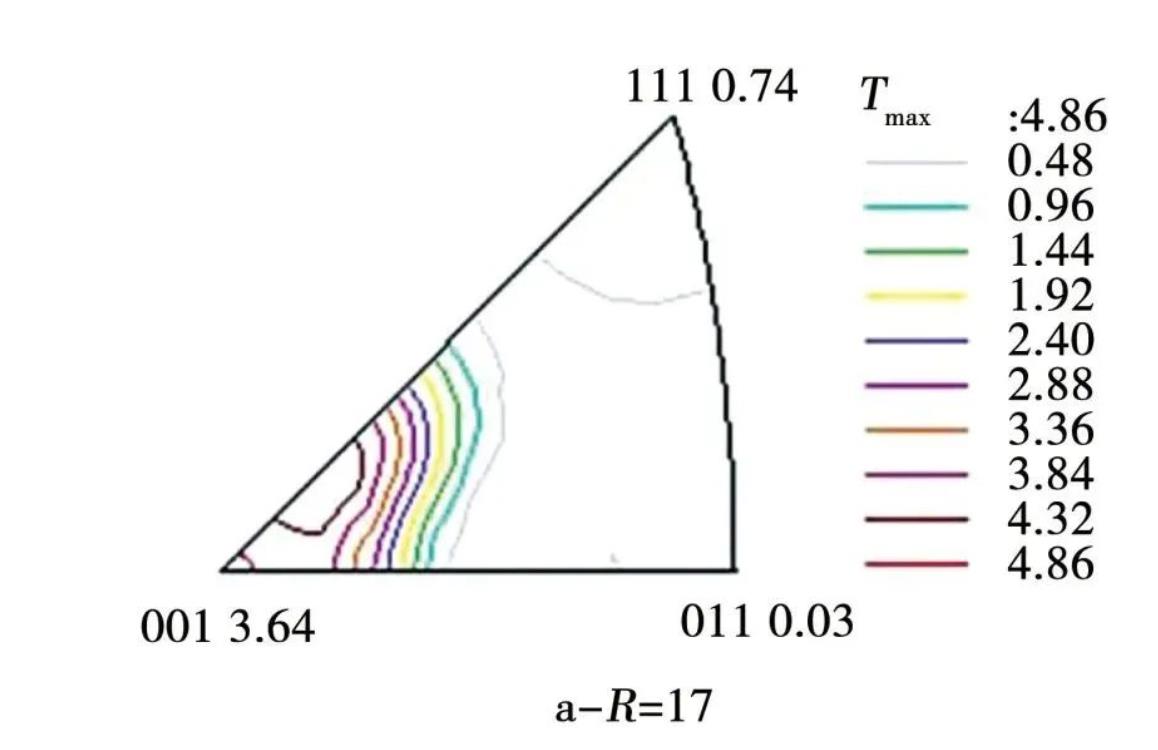

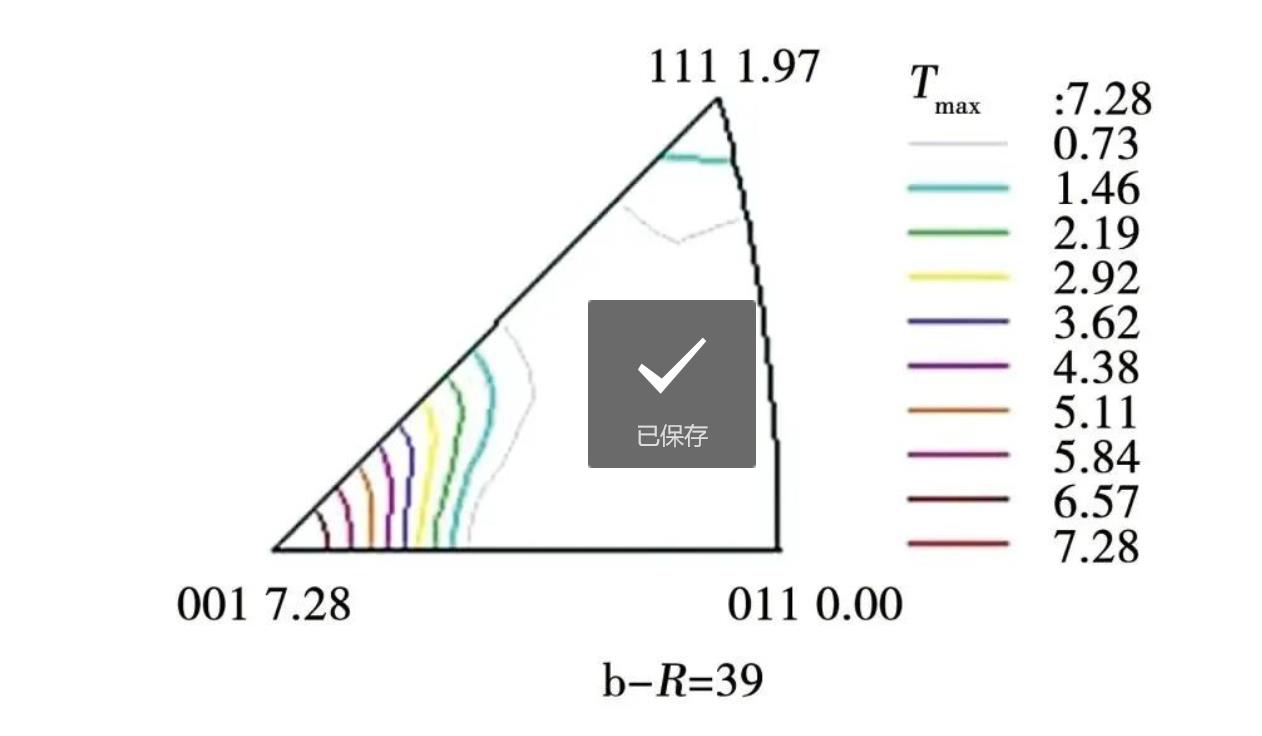

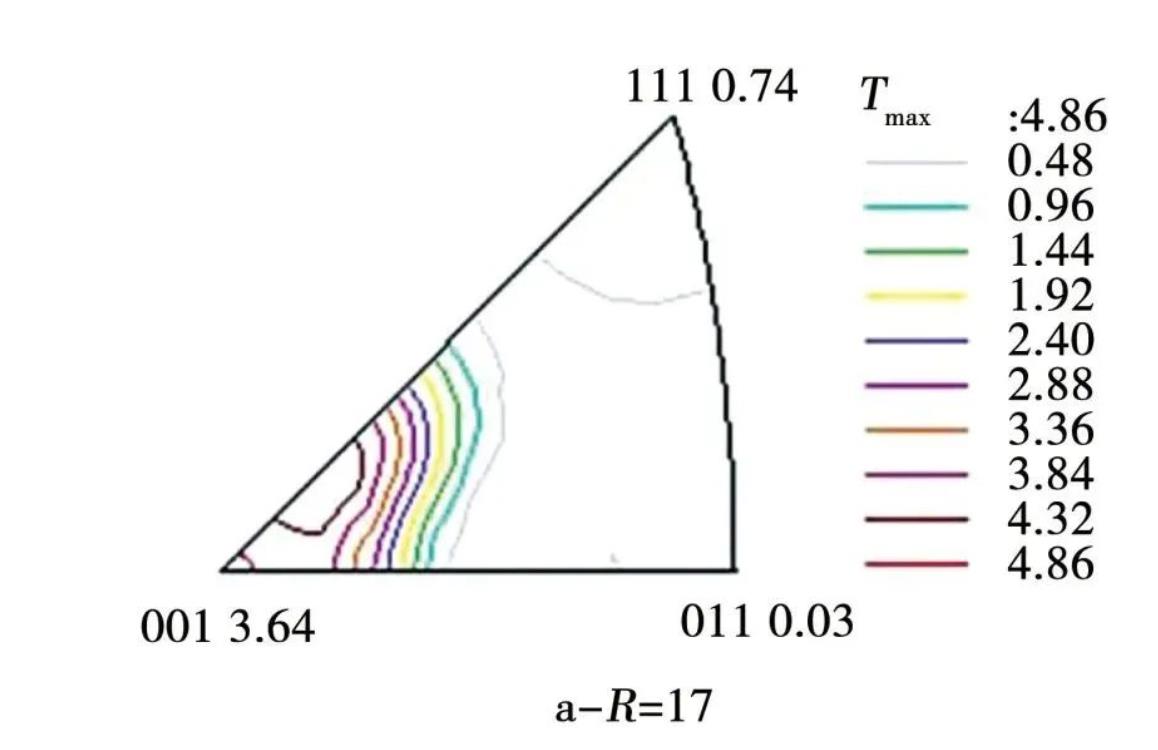

Figure 4 shows the inverse pole diagram of 6063 aluminum alloy bars with different extrusion ratios along the extrusion direction. It can be seen that the microstructure of alloy bars with different extrusion ratios has obvious preferred orientation. When the extrusion ratio is 17, a weak <115>+<100> texture is formed (FIG. 4a). When the extrusion ratio is 39, the texture components are mainly <100> textures with high strength and <115> textures with small amount of weak texture (FIG. 4b). When the extrusion ratio is 156, the texture component is <100> texture with obvious increase in strength, while <115> texture disappears (FIG. 4c). Studies have shown [5] that the face-centered cubic metal mainly forms <111> and <100> silk textures during extrusion and drawing. Once the textures are formed, the mechanical properties of the alloy show obvious anisotropy at room temperature. The texture strength increases with the increase of extrusion ratio, which indicates that the number of grains parallel to the extrusion direction increases gradually, and the longitudinal tensile strength of the alloy increases. The strengthening mechanism of 6063 aluminum alloy hot extruded material includes fine grain strengthening, dislocation strengthening, texture strengthening and so on. In the range of process parameters used in this study, the increase of extrusion ratio can promote the above strengthening mechanism.

.jpg)

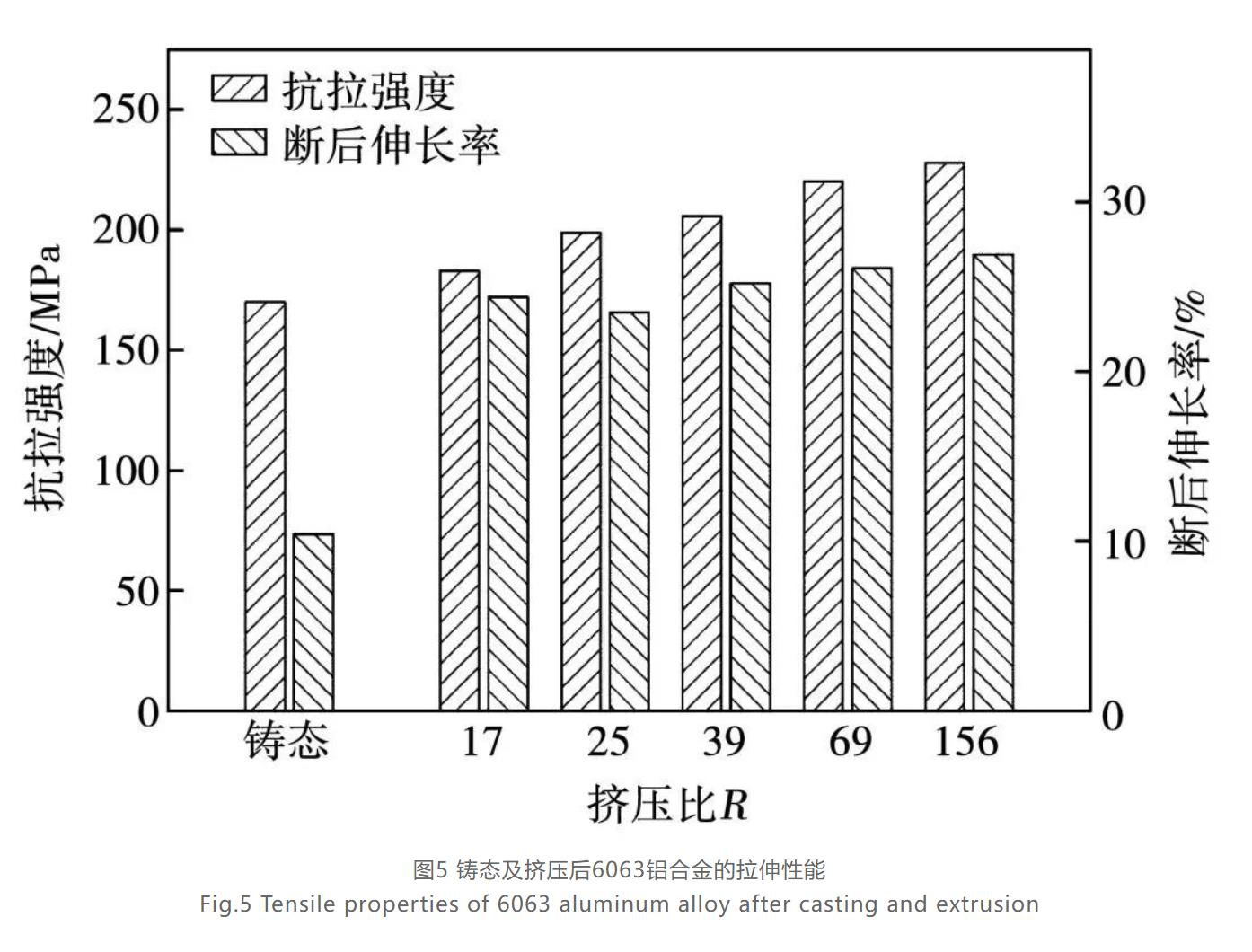

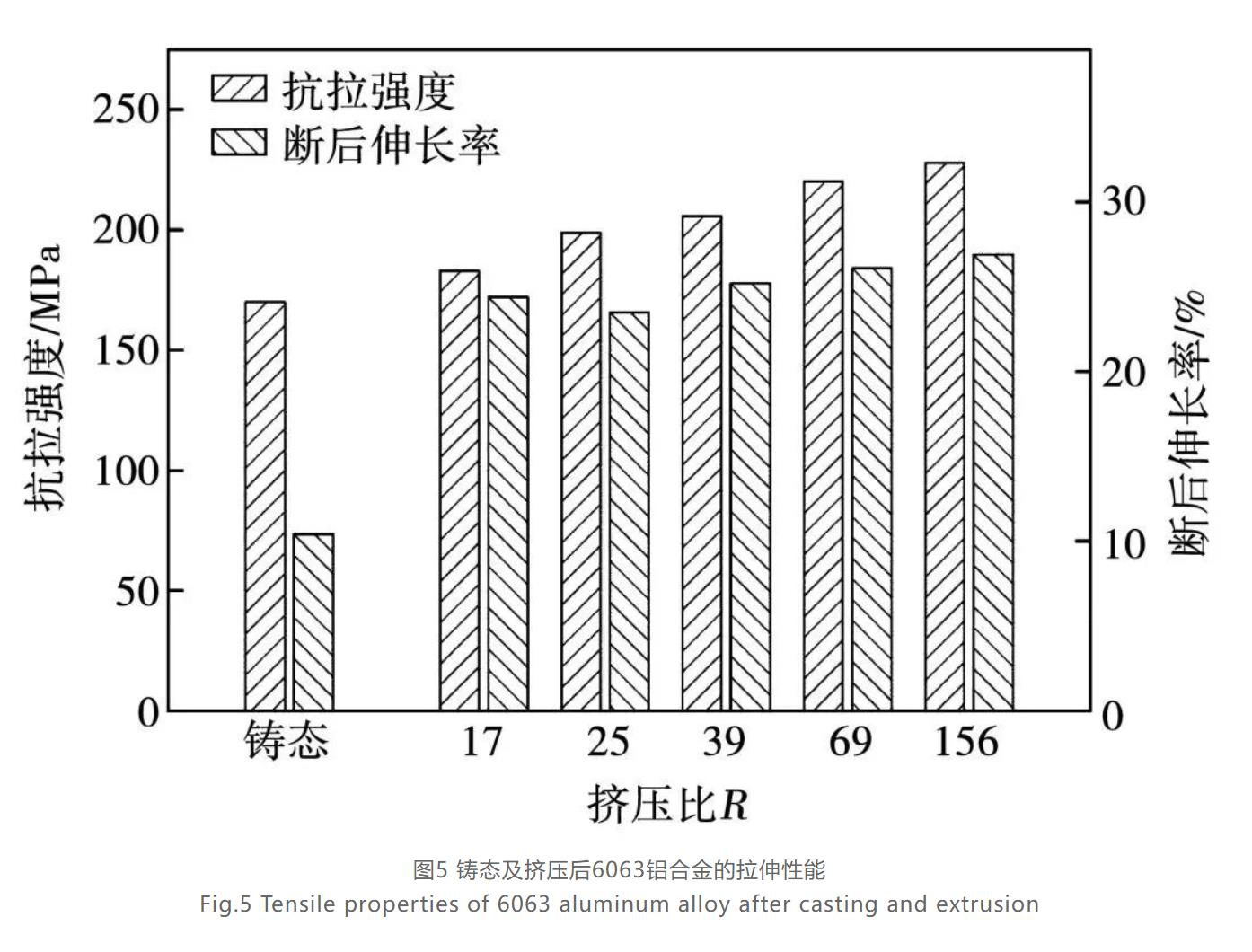

FIG. 5 shows the histogram of tensile properties of 6063 aluminum alloy after deformation with different extrusion ratios. The tensile strength of the as-cast alloy is 170 MPa and the elongation is 10.4%. The tensile strength and elongation of the alloy after extrusion are obviously increased, and the tensile strength and elongation of the alloy gradually increase with the increase of extrusion ratio. When the extrusion ratio is 156, the tensile strength and elongation after breaking of the alloy reach the maximum value, which are 228 MPa and 26.9%, respectively. The tensile strength and elongation of the alloy are increased by about 34% and about 158% compared with that of the as-cast alloy. The tensile strength obtained by large extrusion ratio of 6063 aluminum alloy is close to the tensile strength obtained by four equal channel Angle extrusion (ECAP) (240 MPa)[6], and much higher than that obtained by one ECAP extrusion (171.1 MPa)[7]. It can be seen that large extrusion ratio can improve the mechanical properties of the alloy to a certain extent.

The mechanical properties of the alloy are enhanced by the extrusion ratio mainly from the strengthening of fine crystals. With the increase of the extrusion ratio, the grains are refined and the dislocation density increases. More grain boundaries in the unit area can effectively hinder the dislocation movement and combine the effects of dislocation mutual movement and entanglement, thus improving the alloy strength [8-10]. And the finer the grain, the more fold the grain boundary bend, the plastic deformation can also be dispersed in more grains, which is not conducive to the formation of cracks, more conducive to the propagation of cracks, in the fracture process can absorb more energy, so as to improve the plasticity of the alloy.

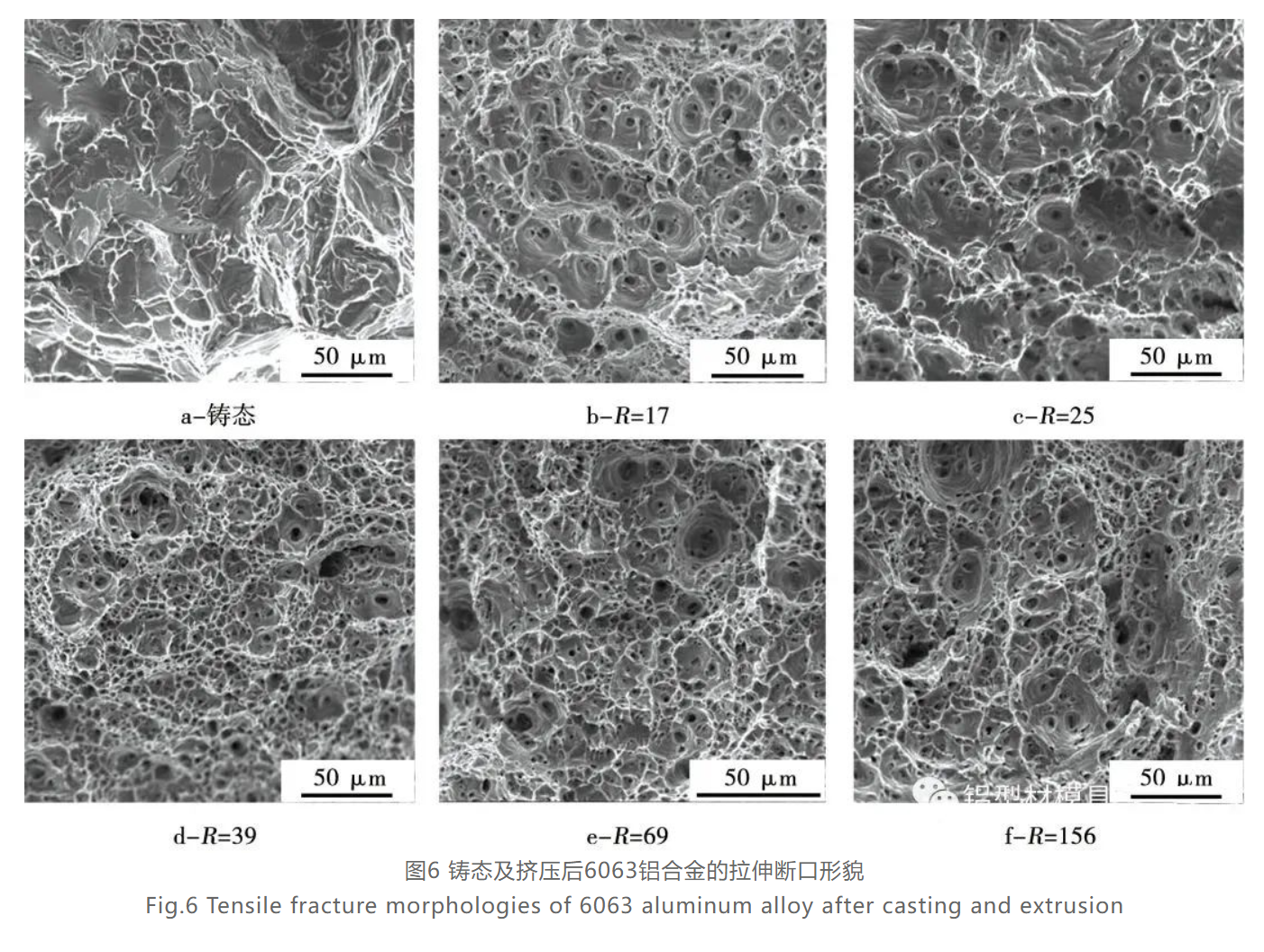

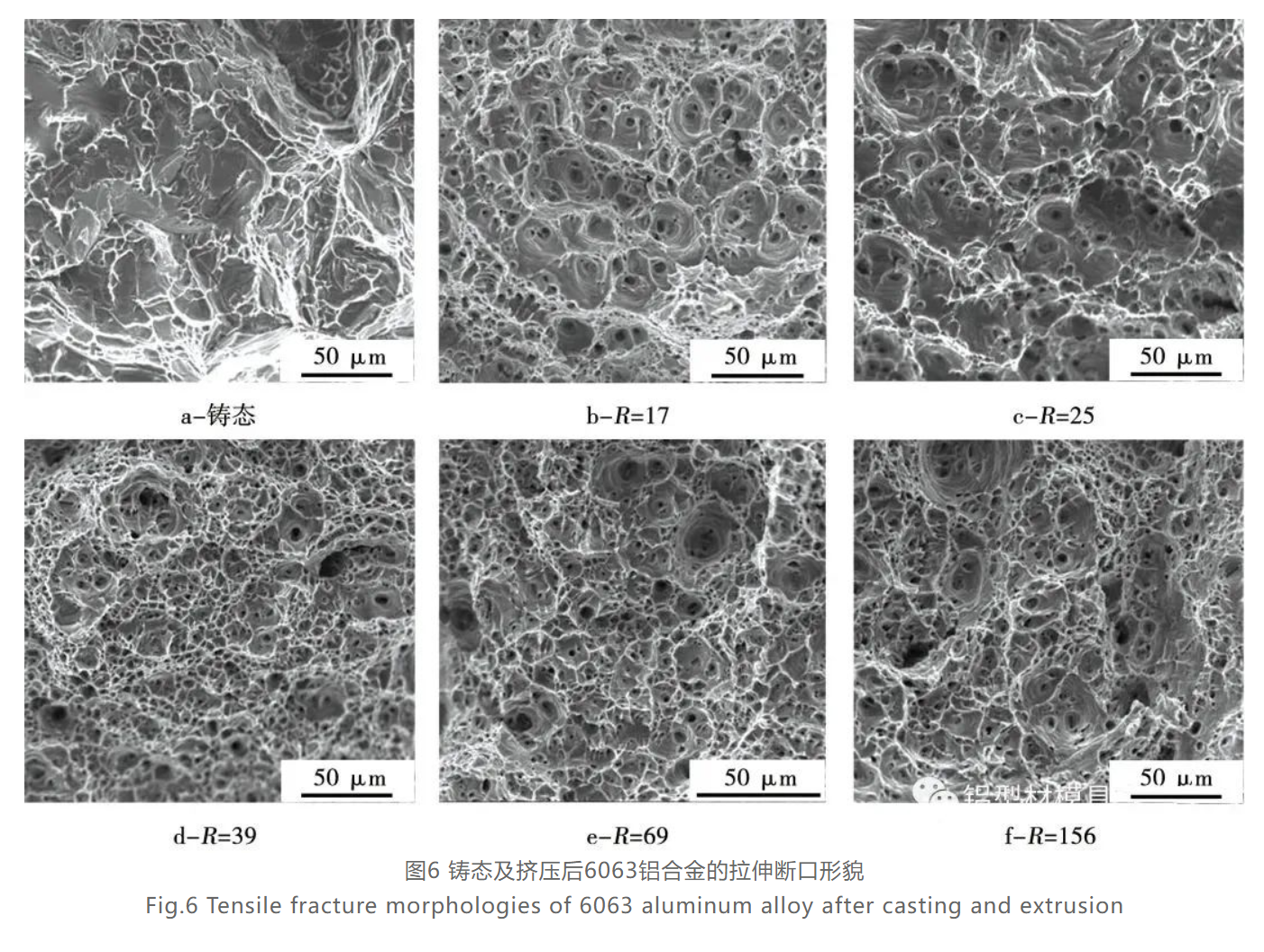

The tensile fracture morphology of the alloy after deformation with different extrusion ratios is shown in Figure 6. No dimple was found in the fracture morphology of the as-cast sample (FIG. 6a), and the fracture mainly consisted of flat region and tearing edge, indicating that the tensile fracture mechanism of the as-cast alloy was mainly brittle fracture. The fracture morphology of the alloy changes greatly after extrusion, and the fracture is composed of a large number of equiaxial dimples, indicating that the fracture mechanism of the alloy changes from brittle fracture to ductile fracture after extrusion. When the extrusion ratio is small, the dimple is shallow and the dimple size is large, and the distribution is uneven. With the increase of extrusion ratio, the number of dimples increases, and the dimple size becomes smaller and evenly distributed (FIG. 6B-F), which means that the alloy has better plasticity, which is consistent with the above mechanical properties test results.

In this experiment, the influence of different extrusion ratios on the microstructure and properties of 6063 aluminum alloy was analyzed under the condition that the billet size, ingot heating temperature and extrusion speed remained unchanged, and the conclusions were as follows:

1) Dynamic recrystallization occurs in the process of hot extrusion of 6063 aluminum alloy. With the increase of extrusion ratio, the grains are continuously refined, and the grains elongated along the extrusion direction are transformed into equiaxial recrystallization grains, and the <100> silk texture strength is continuously increased.

2) Due to the effect of fine grain strengthening, the mechanical properties of the alloy increase with the increase of the extrusion ratio. In the range of the test parameters, the tensile strength and elongation of the alloy reach the maximum value when the extrusion ratio is 156, which are 228 MPa and 26.9%, respectively.

3) The fracture morphology of the as-cast sample is composed of flat region and tear edge. After extrusion, the fracture is composed of a large number of equiaxial dimples, and the fracture mechanism changes from brittle fracture to ductile fracture.

.jpg)